Tagger seal is directly connected with the drug so it is the primary packaging material. It is used in many manufacturing, but probably the most common use is cap sealing. It is a non-contact method of heating the top of plastic and glass containers to achievers to achieve an airtight seal by heating the interior seal of the container.

It’s made from cardboard, aluminium foil, adhesive, and sealing film like LDPE. Tagger seal has a wide range of uses it can be used to seal plastic caps made of PP, PS, PE, and ART paper cups laminated with plastic film.

Tagger seal has been mature and extensive, it is widely used for many advantages. The product reaches the customer in hand with clean, net, safe and effective cap lid sealing with sealing effects.

Tagger seal provides the product with moisture-proof, leak-proof, and fresh-keeping effects. It also has anti-countering effecting and anti-theft properties in addition to company logos and advertisements that can be printed on the sealing film to achieve promotional effects.

It is an important packaging material so its quality is also better than better. We follow step by step below some testing parameters,

Table of Contents

1. Description:

soft tampered plain circular aluminium foil laminated with low-density polyethene film.

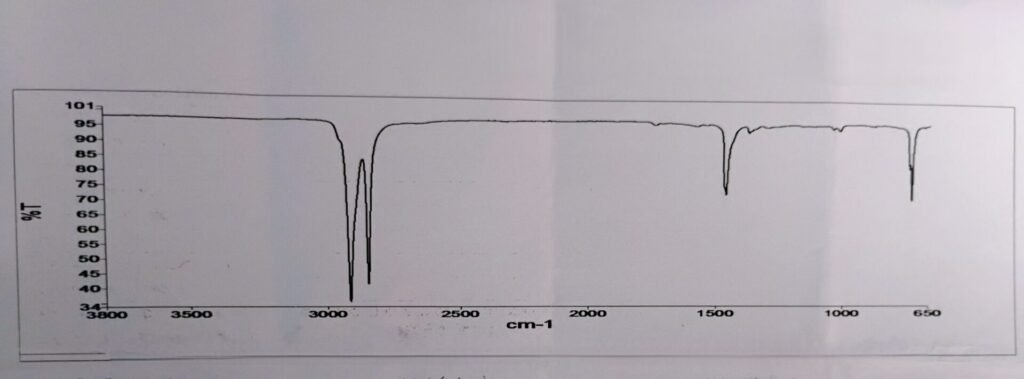

2. Identification of LDPE film

This test is performed by FTIR instrument, LDPE-coated Tagger Seal is in contact with the drug so the contact layer is LDPE then we identification test performed with LDPE.

Its standard is LDPE match with the same wave number. We plotted the spectra is wave number is 3800-650cm-1 standard and test

The IR Spectrum of the LDPE side of the sample matches with the IR spectrum of the corresponding working standard.

3. Identification of chemical method:

Weight the aluminium foil 15 mg sample and put it in a beaker mix 30ml 1NHCL then heat the beaker aluminium foil to dissolve, in solution add about 0.5 ml conc HCL and thioacetamide regents, no precipitate is formed, add dropwise NaoH solution, a gelatinous white precipitate is formed which dissolve on further addition of 1NaoH Solution after gradually addition ammonium hydroxide solution .gelatinous white precipitate is re-formed

4. Diameter of seal:

Selected the sample and measure the diameter with the help of a measuring scale.

5. Grammage test

Total Grammage: selected 3 samples in the stock sample. Cut the sample 5 x 5 cm by the GSM plate. Take the weight on an analytical balance. One by one note the reading and calculate the GSM by the GSM formula,

Total GSM= Weight x 400 (if the sample cut the 5 x 5 cm) unit is gm/m2 = G

Grammage of Aluminium: take the total grammage sample dip it in acetone boil till both layers separate. A layer of aluminium and ldpe cool and dry at room temperature, then take the weight of aluminium at analytical balance,

Grammage of aluminium = Weight x 400 (if the sample cut the 5 x 5 cm) unit is gm/m2 = G1

Grammage of LDPE= G-G1 Weight x 400 (if the sample cut the 5 x 5 cm) unit is gm/m2

6. Thickness:

Selected the sample and measured the thickness with the help of a Vernier calliper. One by one take the reading and note down the reading.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] selected tagger seal sample cut the sample 10 x 10 cm or 5 x 5 cm it a suitable size with the help of a GSM Plate. At different […]