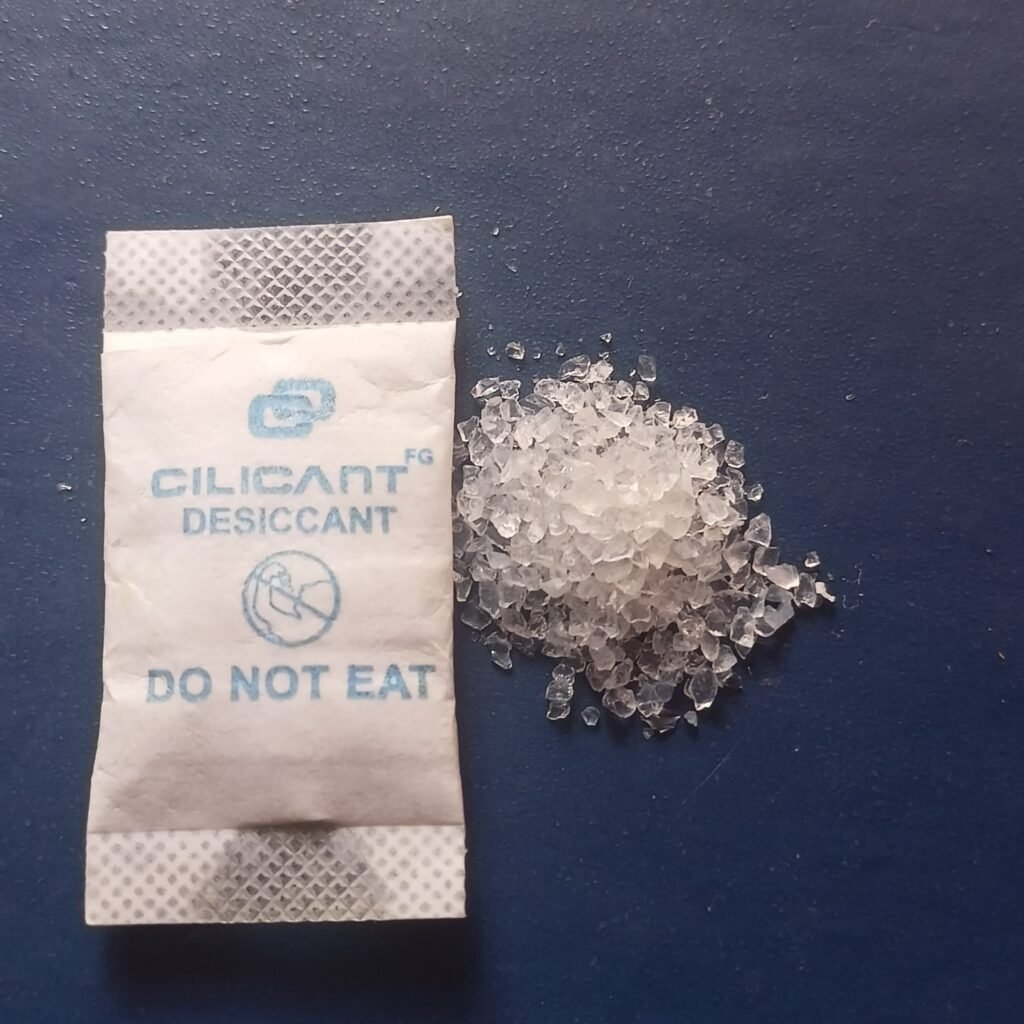

Silica gel sachet is a primary packaging material.it is made from silicon di-oxide being harmless hence this packet can be used with food containers and pharmaceutical containers. Porous, granular, non-toxic silica with a high absorbent capacity, standard-grade silica can absorb 40% of its weight of water from the environment.

Silica gel is the most common type of orange, blue, green (indicating), and white (non-indicating) beads—molecular sieve in Tyvek, composite paper and polyester clothing, transparent bag, and non-woven material.

Silica gel sachets usually have the words “DO NOT EAT” printed on them but its silica gel is non-toxic. However, cobalt is added to self-indicating silica gel which makes it a toxic substance, for this reason, we ensure these packets don’t make contact with food.

Silica gel sachets are used to protect items from moisture and keep things dry. So its quality is better than we have silica gel sachet testing parameters using below,

Table of Contents

1. DESCRIPTION:

white color silica gel contained in a sachet in a sachet made up of uncoated Tyvek. printed on ” DO NOT EAT”

2. IDENTIFICATION

Identification A: take 5 mg of sample silica gel in Platinum crucible, add 200 mg of anhydrous potassium carbonate, and mix it. Then heat on a hot plate for 10 min till red heat over, then cool. Dissolve 2 ml of water slowly and add 2 ml of Ammonium Molybdate TS.

Then the solution is a deep yellow color produced

Identification B- Aluminium: from identification A sample one drop of yellow color solution is taken on filter paper. This filter is an evaporated solvent. Add 1 drop of saturated solution o-tolidine in glacial acetic acid to reduce the silicomolybdate to molybdenum blue. Ammonium hydroxide was placed over the paper. a greenish-blue spot produce

3. Inorganic impurities:

The Silica gel sample solution was analyzed in the led contain by the plasma mass spectrometry (ICP-MS) technique. Its limit is NMT 5 PPM.

4. Soluble ionizable salts:

For Standard: Take 5 g of sample previously dried control sample 1mg/ml of anhydrous sodium sulfate made to 250 ml.

Take the sample with 150ml of water in a glass beaker and stir for 5 min in a high-speed mixer. Filter the sample, wash the mixer, and filter with 100 ml water. The silica gel sample dilutes the filtrate with water to 250 ml.

Determine the conductance with the help of a conductivity meter, the sample, and the control sample.

Then the result is the conductance produced by the sample is that produced by the control solution NMT 5%

5. PH (4-8):

Take 1.0gm of silica gel sample in a glass beaker. Add 20 ml carbon di-oxide-free water and mix. Take its reading on the PH meter instrument Its reading is 4-8

6. Check for contamination:

the silica gel sachet is free from dust, particles, and other contamination on both sides of the sachet.

7. Dimension:

Length: Take 5 silica gel sachets measuring the length with the help of a Vernier caliper

Width: Take 5 silica gel sachets measuring the width with the help of a Vernier caliper

8. Weight of silica:

Take 5 samples of silica gel sachet and take Petry dish tare on the balance and one sachet open sachet take the silica wt. repeat the procedure remaining sachets.

9. Adsorption capacity:

this test is performed in two part

- Take silica gel from sachet. The tare weight of the Petry dish is called W1. Then the weight taken 10 gm of silica gel is called W2. After the sample is placed in a humidity chamber it’s a temperature 250 c ±2 at 40% ±5 RH for 24 hours.

Then after 24 hours sample discharge cool room temp. The taken weight is called

Adsorption% = {(W3-W2)/( W2-W1)} x100 %

Its results NLT 19 %

2. Take Decicator without silica gel. Place a solution of saturated potassium bromide in the decicator. It maintains a temperature of 250 c ±2 and a humidity of 80% ±5 maintain.

Take silica gel from the sachet. The tare weight of the Petry dish is called W1. Then the weight taken 10 gm of silica gel is called W2 after the sample is placed in a desiccator.

The humidity chamber has a temperature of 250 c ± 2 at 80% ±5 RH for 24 hours.

Then after 24 hours sample discharge cool room temp. The taken weight is called W3

Adsorption% = {(W3-W2)/( W2-W1)} x100

Its results NLT 27 %

10. Residue moisture:

Take silica gel from the sachet. The tare weight of the Crucible is called W1. Then the weight taken 3 gm of silica gel is called W2. After the sample is placed in a hot air oven at 1500 C it’s a temperature 1500c ±2 for 3 hours.

Then after 3 hours, the sample discharge is cooled in a desiccator. The taken weight is called W3

Residue moisture % = {(W3-W2)/( W2-W1)} x 100

Its results NMT 3%

11. Assay:

Take a clean platinum crucible and add 1gm silica gel sample to tare platinum crucible (W1). Ignite at 10000C For 1 hour in a muffle furnace. Cool in a desiccator and weight (W3) add 3 drops of sulfuric acid and ethanol (95%) to sample complete moisture. add 15 ml of hydrofluoric acid. Evaporate to dryness in the fume hood on a hot plate at 1000c ±5, avoiding loss from sputtering, wash the sides of the platinum crucible with 10 ml hydrofluoric acid and add 0.5 ml sulfuric acid to evaporate to dryness. Place the sample in a muffle furnace ignite at 10000C FOR 30 Min, cool in a desiccator, and weigh (W4)

The difference between the final weight and the weight of the initially ignited portion represents the weight of silica

%Assay = [{(W3-W1)-(W4-W1)}\(W3-W1)]X100

W1=Platinum crucible weigh

W3= Weight of crucible+ silica gel sample (after ignition)

W4=Weight of crucible + sample (after treatment)

Its results NLT 95%

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.