A sachet is the primary packaging material. Pharma sachets packaging is a four or three-layer, pack made of various materials such as paper plastics, and aluminium. It also offers retention of flavors corresponding to longer shelf life. It presents a great packaging method that can help in effectively strong all types of dry products and dietary supplements.

The use of packaging of fillers, sweeteners, blinders, powders blends, capsule fillings, flavors and solubilizers, disintegrate giants, etc. are some excipients that the sachets can hold efficiently.

There are many types

- Sugar

- ORS

- PRE-Biotic

- Silica gel

- Salts

- Cholecalciferol

Another type of sachets which are not maintained on this list

So, it plays an important role in pharmaceutical packaging, we follow some testing parameters to ensure its quality is better

- Description:

printed or unprinted triple laminated three-side sealed sachets

2. Identification of contact layer Sachets:

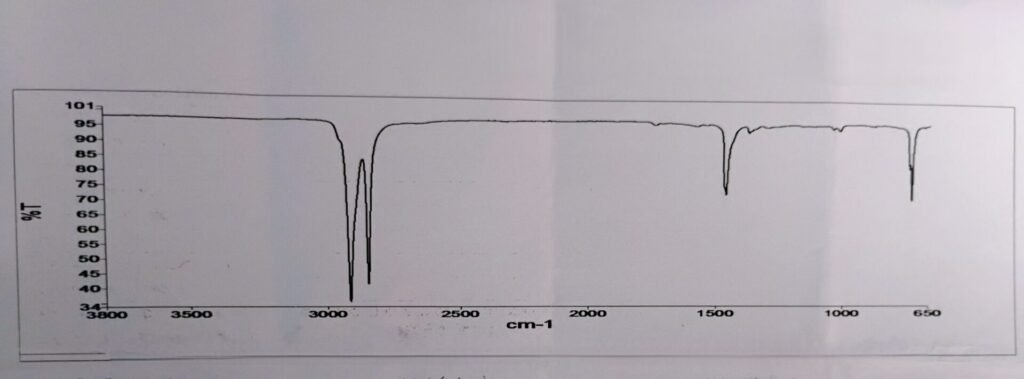

This test is performed by FTIR instrument, selected sample of sufficient quantity sachets. Its contact layer is the LDPE layer then taken LDPE reference standard, scan standard, and sample scan graph are plotted. Is compared with the standard to sample the same 3800-650cm-1 wavelength.

The IR spectrum of the contact layer on the dull side matches the corresponding working standard of the Low-density polyethylene

3. Dimension

Length: Select 5 samples of sachets measure the length with the measuring scale, take readings one by one, and note down the reading.

Width: Select 5 samples of sachets measure the width with the measuring scale, take readings one by one, and note down the reading.

4. Thickness:

Measure the total thickness of the sachets with the help of a digital micrometer. Different samples to different positions. Take reading and note it down.

Dip the sample in a beaker containing nitric acid for 10 min, the PET, Aluminium, and LDPE Layer get separated from the triple laminated take out samples from the beaker with the help of forceps and then clean the sample with the help of cotton cloth dipped in ethyl acetate & dry it for 5 min in an oven at 1050c.

The thickness of PET: after a dry layer of PET Layer measure the thickness with the help of a digital micrometer note down the reading.

Thickness of Aluminium: after a dry layer of Aluminium Layer measure the thickness with the help of a digital micrometer and note down the reading.

Thickness of Poly: after a dry layer of Poly Layer measure the thickness with the help of a digital micrometer and note down the reading.

5. Grammage:

Total grammage: take a sample of the sachet. Cut the 10 x 10 cm or 5 x 5 cm with the help of a GSM plate. After weighing the samples individually at an analytical balance record the reading.

Grammage = weight in grams x 100 or 400 (if the sample cut 10 x 10 cm or 5 x 5 cm)

Grammage of PET: Take the sample of the thickness of PET and cut the sample 10 x 10 or 5 x 5 cm with the help of GSM Plate at an analytical balance

Grammage of PET = weight in gram x 100 or 400 (if the sample cut 10x 10cm or 5 x 5 cm)

Grammage of Aluminium: Take the sample of the thickness of Aluminium and cut the sample 10 x 10 or 5 x 5 cm with the help of GSM Plate at an analytical balance

Grammage of Alum = weight in gram x 100 or 400 (if the sample cut 10x 10cm or 5 x 5 cm

Grammage of poly: take the sample of the thickness of Poly and cut the sample 10 x 10 or 5 x 5 cm with the help of GSM Plate at an analytical balance

Grammage of Poly = weight in gram x 100 or 400 (if the sample cut 10x 10cm or 5 x 5 cm

6. Check for contamination

The sachet shall be free from any adherent, delamination of layers, and foreign matter

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] are some pharmaceutical finished products that are used in packaging, like blister packaging and sachet […]

[…] layer laminated with foil. It is used in the pharmaceutical industry in strip packaging, pouches, sachets, lids, and warps. the foil is the lidding foil. This type foil made-strip packaging is child-proof. […]