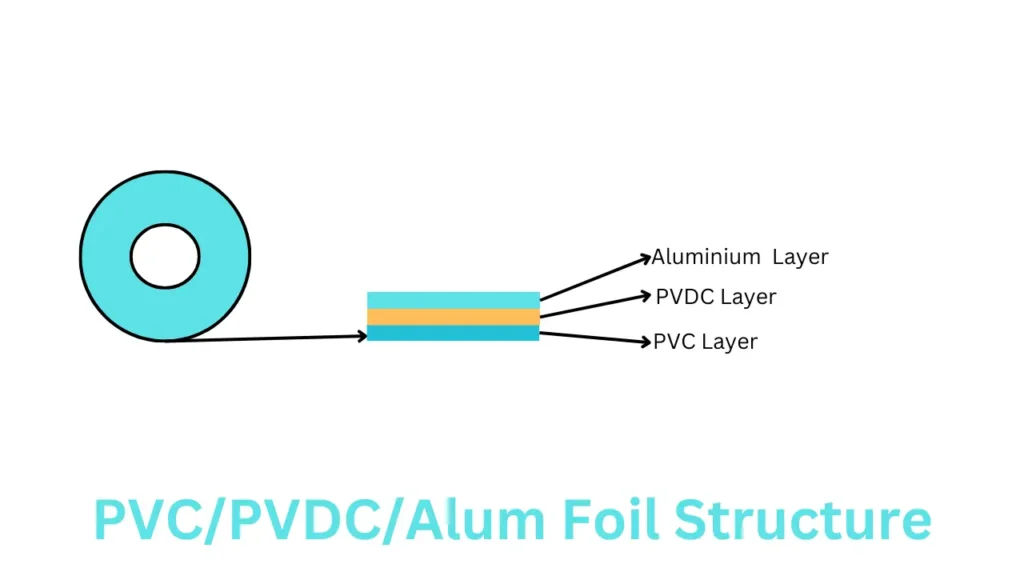

The PVC/PVDC/Alum foil is made from a thin layer of PVDC laminated with PVC on one side and the other side laminated with Aluminium layer. It is foil is multi-structure foil. It is foil used in blister packaging of pharmaceutical products like tablets, and capsules. This foil is a barrier to air, moisture, and the environment.

1.Description:

The thin PVDC layer is laminated with the PVC layer on one side, and the other is laminated with an Alum layer, on the aluminium layer side printed foil or unprinted.

2.Text matter:

The sample PVC/PVDC/Alum foil is printed text matter, the printed text matter matches the shade card or artwork.

3. Color Scheme:

The PVC/PVDC/Alum foil sample is a printed text matter color scheme that matches a shade or Pantone card.

4. Width:

The sample foil testing is the testing width, with the help of a measuring scale. The selected sample measures the width of the sample and notes down.

5. Inner core diameter:

The sample foil PVC/PVDC/Alum is as a roll, the roll inner core diameter measuring the measuring scale. The selected sample measures the width and notes the reading.

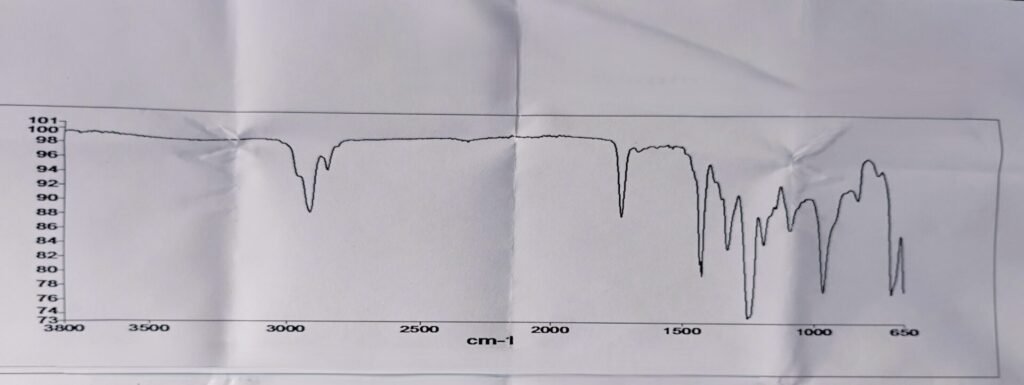

6. Identification by FTIR:

The identification of sample PVC/PVDC/Alum foil is testing of the layer PVC Layer side. The identification testing of PVC Layer with the help of FTIR instrument. The PVC layer matches with the PVC reference standard. The first scan is the reference standard of the PVC layer, then after scanning the graph PVC layer sample, the sample of PVC Layer, and reference standard PVC sample are graph plotted between 3800-650 cm-1 wavelength.

The spectrum of the specimen exhibits major absorption bands only at the same wavelength as the spectrum of the PVC layer sample and reference standard PVC.

7. Grammage of PVC/PVDC/Alum foil:

- Total Grammage:

The selected sample of PVC/PVDC/Alum foil is total Grammage testing, cutting the sample PVC/PVDC/Alum foil 10 x 10 cm or 5 x 5 cm. Take the sample weigh the sample at the analytical balance, and calculate the Grammage calculation by the given formula,

Total Grammage= weigh in grams x 100 or 400 (if the sample cut 10 x 10 cm or 5 x 5 cm)

- For the PVC Layer, PVDC layer and Aluminium layer

Take the sample of the total Grammage sample and dip the sample in a glass beaker containing ethyl acetate. After 20-25 minutes the sample is separated into each layer, PVC Layer, PVDC layer, and aluminium layer. Or not a separated layer till the separated layer. Each layer dries the sample in a hot air oven for 2 min at 700c. Then cool the sample take weigh the sample at the analytical balance. Calculation of the Grammage by the given formula,

PVC layer Grammage =weigh in grams x 100 or 400 (if the sample cut 10 x 10 cm or 5 x 5 cm)

PVDC Grammage =weigh in grams x 100 or 400 (if the sample cut 10 x 10 cm or 5 x 5 cm)

Aluminium Grammage =weigh in grams x 100 or 400 (if the sample cut 10 x 10 cm or 5 x 5 cm)

8. Identification of Aluminum layer:

Take the sample of aluminium layer Grammage, This test is performed to identify aluminium by the chemical method. Take a sample of the Grammage of the aluminium layer. Take in a beaker mix 30ml 1NHCL then heat on a hot plate. The beaker aluminium foil to dissolve, in solution, add about 0.5 ml conc HCL and thioacetamide regents, no precipitate is formed, add dropwise NaoH solution and a gelatinous white precipitate is formed which dissolves on further addition of 1NaoH Solution after gradually addition ammonium hydroxide solution .gelatinous white precipitate is re-formed.

9. Thickness:

The selected sample of PVC/PVDC/Alum Foil the testing total thickness with the help of a digital micrometer, the sample measures the total thickness sample takes the reading, and notes down it.

10. Pinhole testing of PVC/PVDC/Alum foil:

The selected sample tested the pinhole of the PVC/PVDC/Alum Foil with the help of an instrument pinhole tester. The sample was plotted on the back of the light background in the light visual, it presence of background light. The sample is easily identified in the sample. It does not observe the hole in the sample. If the sample has a hole light passed the light, it is easily verified in a pinhole. It test is important for foil in pharmaceutical finished product packaging.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] Clear transparent or colored rigid PVC film coated with […]