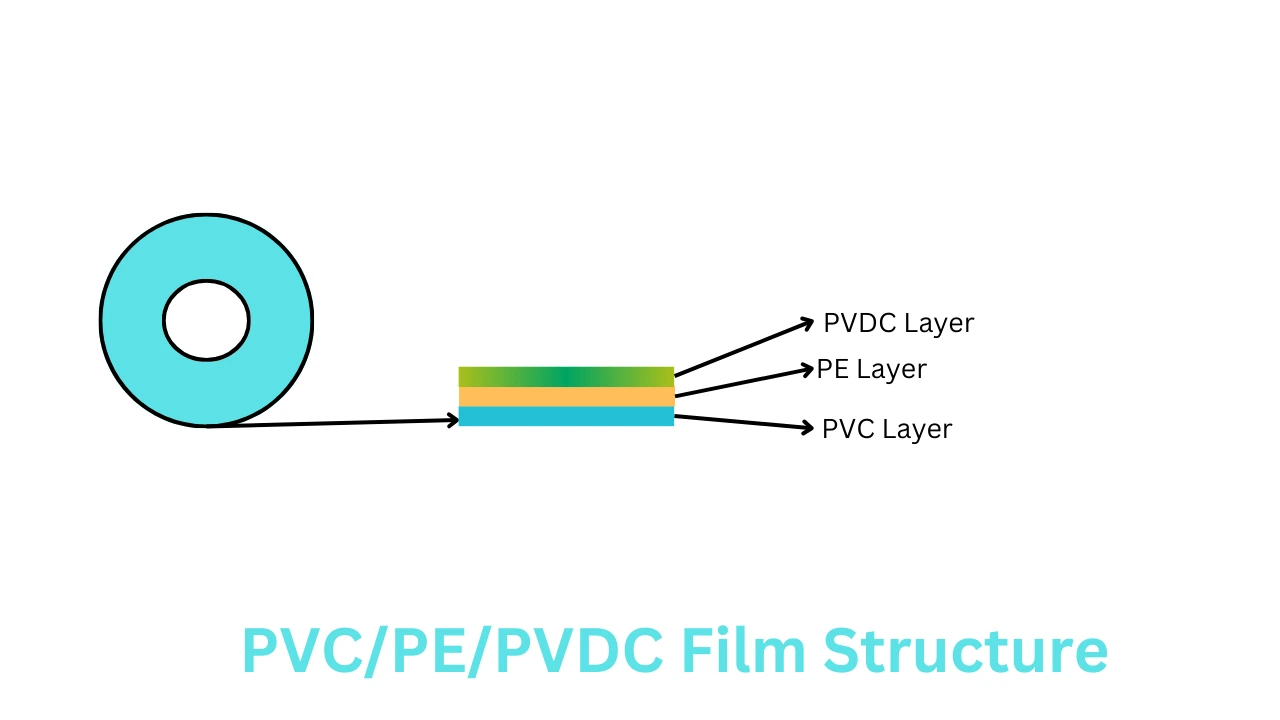

PVC/PE/PVDC foils are directly connected to Drugs so it is called primary packaging material. Polyvinyl chloride/polyethylene/polyvinylidene chloride a triplex layer, PVC is the most common material to use in packaging. PVC blister offers structural rigidity and physical protection, it is hard to collapse when pressed upon for this reason PVC sheet thickness is typically chosen between 200 microns to 300 microns depending upon cavity size and shape.

Polyvinylidene chloride has water barrier and oxygen barrier properties. It is coated with PVC OR Polyethylene(PE). Where the PE layer assists when forming deeper cavities. It is used to laminate with PVC to PVDC layer.

it plays an important role in the packaging of pharmaceutical products so we ensure some parameters of quality,

- Description: A Clear transparent or color rigid PVC film coated with PVDC and PE layer is sandwiched between PVC and PVDC

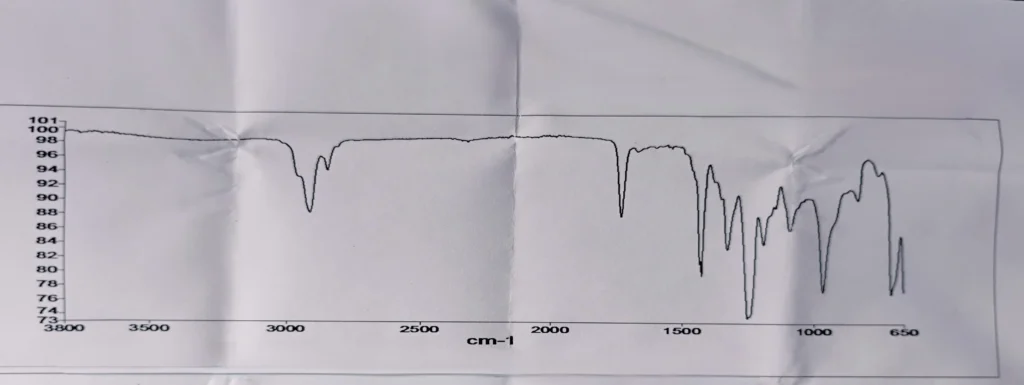

- Identification by FTIR of PVC: This test is performed by an FTIR instrument, cutting a sufficient sample of the PVC side of the sample. Its standard is PVC match with the same wave number. We plotted the spectra in wave number 3800-650cm-1 standard and the sample.

The IR Spectrum of the PVC side of the sample matches the IR spectrum of the corresponding working standard.

PVC of PVC FTIR GRAPH

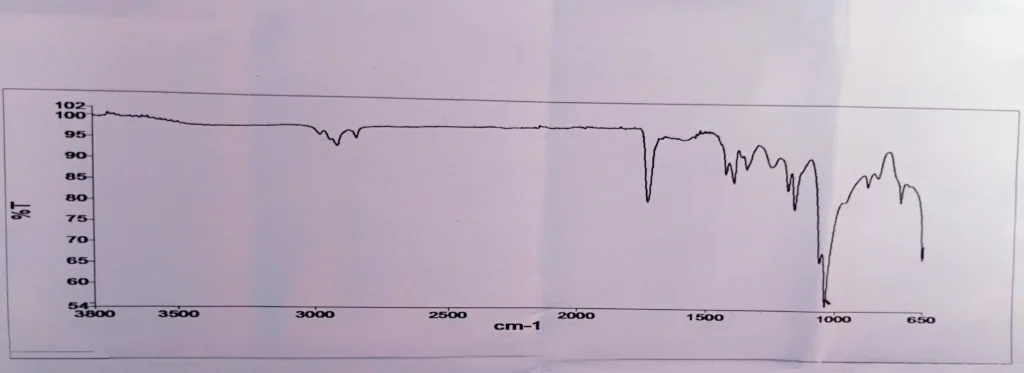

3.Identification by FTIR of PDVC: This test is performed by an FTIR instrument, cutting a sufficient sample of the PVDC side of the sample. Its standard is PVDC match with the same wave number. We plotted the spectra in wave number 3800-650cm-1 standard and the sample.

The IR Spectrum of the PDVC side of the sample matches with the IR spectrum of the corresponding working standard.

PVDC of PVC FTIR GRAPH

4. Morpholine Test

Morpholine Test of PVC- taken selected sample. Carefully take morphine in a dropper. A few drops out on both sides of the surface of the sample. On one side of the sample surface, no color appeared. Its side is identified as PVC.

Morpholine Test of PVC: A few drops out on another side of the sample’s surface. On the side of the sample surface, a yellow color appeared. Its side is identified as PVDC.

Width: the selected sample measures the sample width with a measuring scale. Take a reading at different width positions and take a reading note down.

5. GRAMMAGE OF PVC/PE/PVDC FILM

TEST METHOD-1

Total Grammage: selected the PVC/PE/PVDC sample. Cut the sample 5 different samples 10 x 10 cm with the help of a GSM plate. Weight the sample on an analytical balance. Take a reading and record it.

Calculation

Total Grammage= weight of sample in gram x 100 (if the sample cut 10 X10 cm)

- Grammage of PVDC: The sample is taken from the total Grammage. In a glass, beaker take ethyl acetate dip in the sample completely dip in ethyl acetate regent. After some time wait until the PVDC and PE layers separate from the PVC layer. After separation the PVDC and PE layer samples dry in the hot air oven at 1050c FOR the PVDC and 750 c For the PE Layer Sample.

Cool the sample at room temperature then, Take the weight and calculate the GSM.

Grammage of PVDC= weight of sample in gram PVDC layer X 100 (IF SAMPLE CUT IN 10 X10 CM)

GRAMMAGE OF PE = weight of sample PE in gram X 100 (IF SAMPLE CUT IN 10 X10 CM)

Grammage of PVC Layer: measure the GSM of the PVC layer with the help ofgiven formula

Grammage of PVC Layer = total Grammage – (Grammage of PVDC + Grammage of PE layer)

GRAMMAGE TEST: METHOD-02

- Grammage of PVDC: place the sample of Total grammage of the sample in acetone. completely dip the sample in acetone for 5 to 10 min check intermittently whether the PVDC layer separating or not. After the PVDC layer is separated dry it in a hot air oven at 1050 C for 5 min cool at room temperature then take the weight of the PVDC Layer.

Grammage of PVDC= Weight of PVDC in gram X 100 (if the sample is cut 10 x 10 cm)

Take the sample (after removing the PVDC Layer) and make the solution of 40:60 glacial acetic acid and water. Dip the remaining sample in the solution. Boil it for 5 min, and the layer is separated into two parts. Wash the sample with the water, PE Layer dry it 750c for 5 min in a Hot air oven. Cool the sample and weigh it.

Calculate the Grammage of the PE layer

Grammage of PE Layer= Weight of PE layer in gram x 100 (if the sample is cut 10 x 10 cm)

the PVC layer will absorb the solvent and swell and hence it does not give the accurate gsm of the PVC layer. then the PVC layer does not measure the GSM, WE CALCULATE GSM of the PVC layer with the help of total grammage, PVDC, and PE layer

Grammage of PVC= total Grammage- (Grammage of PVDC+ Grammage Of PE layer)

6. Thickness:

- The thickness of Total film (mm): The selected sample has measured the sample with the help of a digital micrometer taking readings and noting them.

- Thickness of PVDC film: the sample of a Grammage of PVDC taken it. Measure the thickness of PVC film at different points with the help of a digital micrometer. Take reading and note it down.

8.Pin Holes: this test is performed with a pinhole tester. Put the selected sample on the surface of the hole tester. Its background light is clear visually the sample has holes available or not.