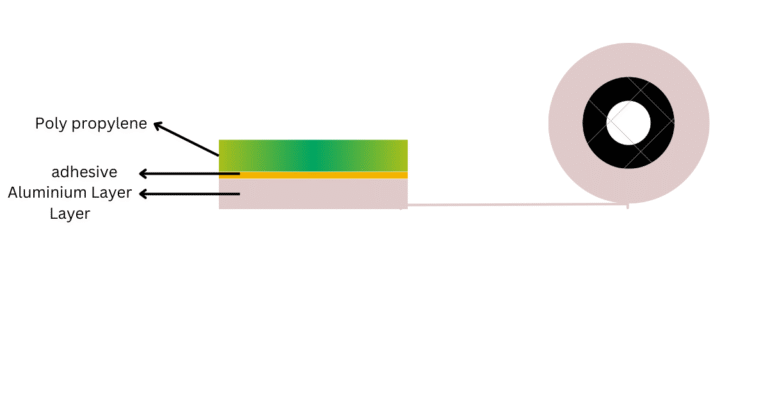

PP Coated Aluminium foil

Polypropylene is the second most important plastic although polypropylene is chemically relatively similar to PE, it is much harder, stronger, and has a higher thermal load capacity. More than one-third of synthetic fibres are produced based on pp. Important application areas are packaging film and rigid packing.

Aluminium foil

Aluminium foil is a thin-rolled sheet of allotted aluminium varying in thickness found about 4-150 μm. Aluminium has excellent physical protection and barrier properties, formability and decorative potential, recyclability and consumer acceptance, making it one of the most common metal-based packing materials.

PP-coated aluminium foil is produced through solvent-based lacquer lamination with a pp film the solvent-based adhesive, for example, a polyurethane use an adhesive. The adhesive is the aluminium foil coated with the pp film between two rollers into coated aluminium foil.

PP-coated aluminium foil is useful to use in the packing of pharmaceutical finish products. Its testing parameter is useful for ensuring better quality of the pp-coated aluminium foil.

- Description:

PP-coated aluminium foil has two types: printed and unprinted. We physically verify that no smudging or test is blundering on the printed foil of text matter. Printing foil also verifies the eye point.

2. Test matter & colour

if the foil is printed, test matter is compared with a standard shade card or artwork.

3. Width:

measure the aluminium foil width help of a calibrated measuring scale.

4. Inner core diameter:

measuring inner core diameter by calibrated measuring scale

4. Identification of aluminium:

chemical method

the chemical method,Weight the aluminium layer 15 mg sample and put it in a beaker mixing 30ml 1NHCL then heat the beaker aluminium foil to dissolve, in solution add about 1 ml HCL and 1 ml of thioacetamide regents, no precipitate is formed, add drop wise NaoH solution, a gelatinous white precipitate is formed which dissolve on further addition of 1NaoH Solution after gradually addition ammonium hydroxide solution .gelatinous white precipitate is re-formed.

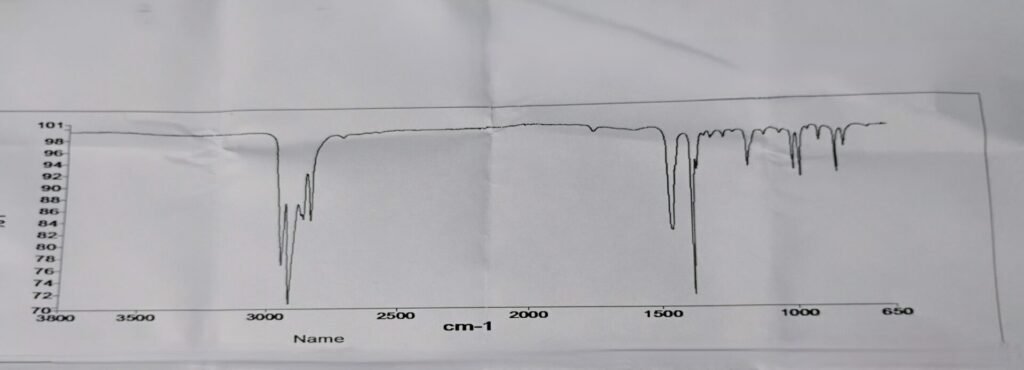

IDENTIFICATION BY FTIR

This test is performed by FTIR instrument, Pp-coated aluminium foil is in contact with the drug so the contact layer is polypropylene then we identification test performed with polypropylene. Its standard is polypropylene match with the same wave number. We plotted the spectra is wave number is 3800-650cm-1 standard and test

Grammage

PP-coated aluminium foil (printed) cut the sample 10×10 cm with the help of a GSM plate. Then the sample wt. on analytical balance the calculate the GSM,

Total Grammage= Weight of sample in gram x 100 (if the sample cut the 10 x 10 cm) = G

Then put the sample in a beaker and take acetone in a beaker. Heat the sample on a hot plate the samples are separated into two layers polypropylene and Aluminium. Cool and dry the room temp. Then taken wt. of aluminium layer wt. at analytical balance. GSM calculation by the given formula

Grammage of Aluminium = Weight of sample in gram x 100 (if the sample cut the 10 x 10 cm) = G1

Grammage of polypropylene = Total Grammage- Grammage of aluminium

Other mathod

- Make a solution of 10% NaoH. Dip the sample in its solution after some time, and the aluminium layer dissolved. The remaining layers are found in the Polypropylene Layer. Dry it and after taking the weight sample

- Grammage pp layer = weight in gram x 100 or 400 ( if the sample is cut 10 x 10 cm or 5 x 5 cm)

Thickness:

the measurement of the total thickness of aluminium foil with the help of a calibrated digital micrometre. It also measured the total thickness of the aluminium layer taking the sample of GSM testing to separate the layer from LDPE. Take reading record it.

Pin hole:

take the sample of aluminium foil test performed by Illuminated magnifier tester instrument. Its instruments are in the background white light. Put the sample on the front. We neck eye verify the sample. Ensure the sample has no pine hole

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.