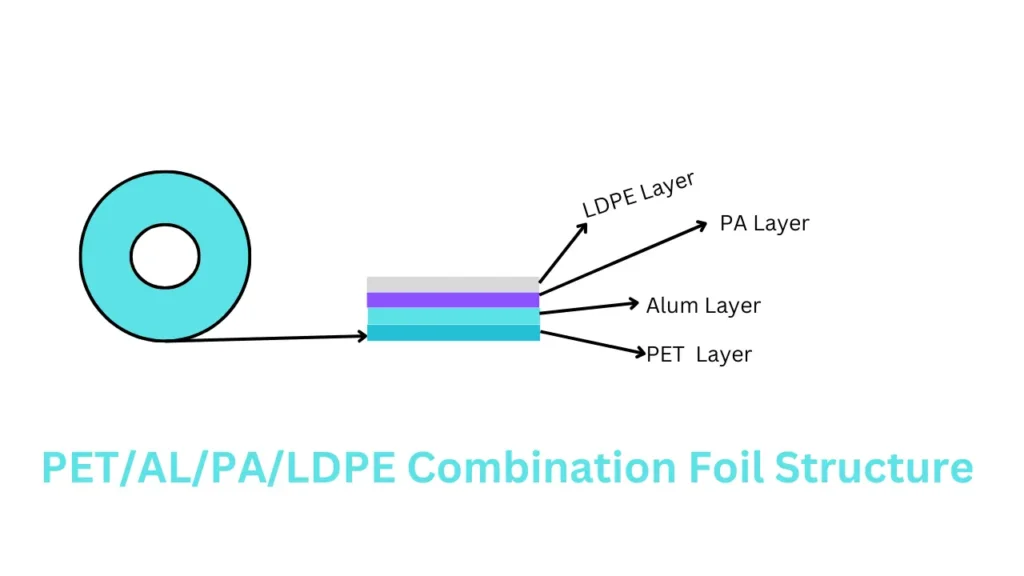

PET/AL/PA/LDPE Foil is made from a thin layer of aluminium laminated with a polyamide layer and Low-Density polyethylene on one side and another side of aluminium laminated with PET (Polyethylene phthalate). It is a multi-structure foil. It is different- different components are PET, AL, PA, and LDPE. All components have different properties. It makes good properties foil which are some pharmaceutical finished products that are used in packaging, like blister packaging and sachet packaging.

This combination foil is designed to provide a high level of protection for a wide range of products, including food, pharmaceuticals, and other sensitive items. It combines the benefits of each material to offer durability, barrier properties, and effective sealing.

So, it’s important is increase to the packaging so its quality is also better, we tested every parameter given below parameter

- Description:

The thin layer of alum foil is laminated on one side with originated polyamide and low-density polyethylene, and on another side PET (Polyethylene terephthalate). One side is printed or plain and the other side is plain.

2. Text Matter:

If the PET/Al/PA/LDPE Combination foil is printed match it with a shade card or artwork of text matter.

3. Color scheme:

The color scheme of the text matters of the printed foil matches with the shade card or Pantone card.

4. Inner core diameter:

The foil is in the form of the roll, the roll of inner core diameter measuring with a measuring scale. Take measure the diameter and note down the reading

5. Identification by FTIR:

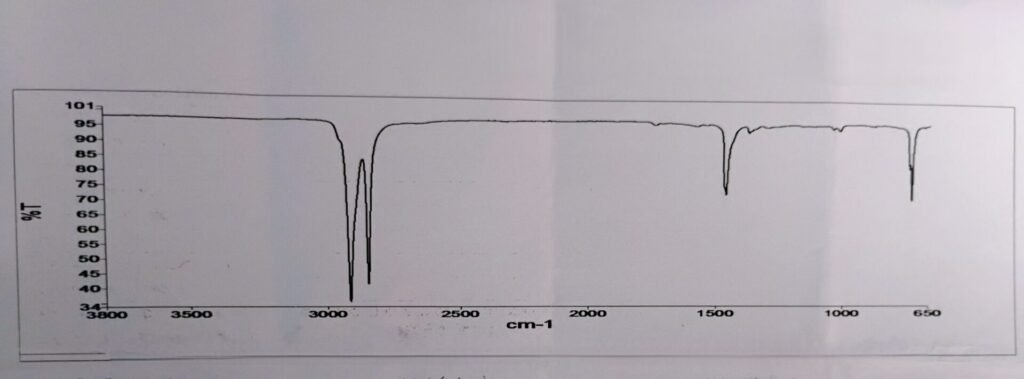

- For LDPE Layer:

This test performs identification by FTIR of the reference sample and sample identified by the same wavelength, and the sample is identified whose molecular structure is the same reference standard and a sample of LDPE Layer.

The PET/Al/PA/LDPE combination foil is Identification testing of the LDPE Layer side. Take a sufficient sample, and take the reference sample of the LDPE. First the reference sample and after the sample was scanned at 3800-650 cm-1 wavelength.

Compared concerning the sample, then The IR Spectrum of the LDPE side of the sample matches with the IR spectrum of the corresponding reference standard.

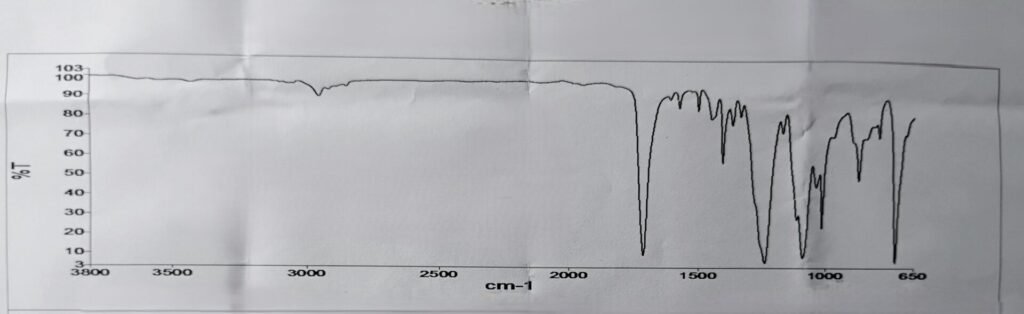

- For PET Layer:

The PET/Al/PA/LDPE combination foil is Identification testing of the PET Layer side. Take a sufficient sample, and take the reference sample of the PET. First the reference sample and after the sample scanned at 3800-650 cm-1 wavelength.

Compared with reference to the sample, then The IR Spectrum of the PET side of the sample matches with the IR spectrum of the corresponding reference standard.

6. Grammage:

- Total Grammage

The selected sample of PET/Al/PA/LDPE combination foil Grammage testing then cut 10 x 10 cm or 5 x 50 cm or a suitable size with the help of a Gsm plate. Weight the sample at analytical balance, and calculation by the given formula,

Total Grammage= weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

For the LDPE layer:

Take the sample of total Grammage sample and completely dip it in a glass beaker containing acetone. Boiling the sample containing glass beaker then after the LDPE layer dissolve. After dissolving the sample take and wash the water and dry the remaining sample in a hot air oven for 2 min at 700c. After cooling then take weight at analytical balance, the calculation by the given formula,

Remaining sample Grammage =weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

LDPE Layer Grammage = total Grammage – Remaining sample Grammage.

- Take the left-out sample from the LDPE Layer. Dip the sample in 25% of glacial acetic acid and slightly boil after some time the polyamide layer, the PET Layer, separated from the aluminium layer. Dried the sample in a hot air oven at 700 c for 2 min. then cooling the sample and take the weight of the sample at the analytical balance.

PET Layer Grammage= weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

PA Layer Grammage= weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

Alum Layer Grammage= weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

7. Thickness:

- Total thickness:

Take a sample of PET/Al/PA/LDPE Combination foil measure the sample with the help of a digital micrometer, take the reading, and note it down.

- PET Layer thickness:

Take a sample of PET Layer Grammage sample measuring the sample with the help of a digital micrometer, take a reading, and note it down.

- PA Layer thickness:

Take a sample of PA Layer Grammage sample measure the sample with the help of a digital micrometer, take a reading, and note it down.

- Alum Layer thickness:

Take a sample of Alum Layer Grammage sample measure the sample with the help of a digital micrometer, take a reading, and note it down.

8. Pinhole:

Selected the sample in a lot. The sample put on the platform of the pinhole tester instrument sample visually checked with the help of background light. It’s no hole appears on the surface of the sample. Testing is important for foil the foil has no hole in the sample.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] PET/Alum/PA/LDPE Foil is made of an Aluminium layer laminated with a PET (polyethylene terephthalate) Layer on one side […]