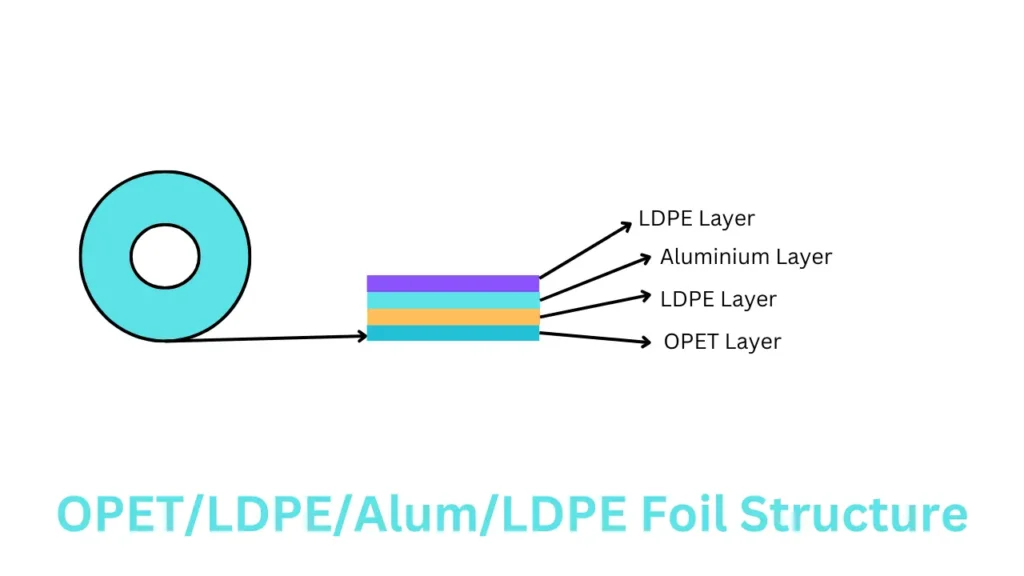

The OPET/LDPE/Alum/LDPE Foil is made from the structure of the aluminium layer. It is laminated with LDPE (Low-density polyethylene) on one side and another side, an LDPE layer with OPET layer (Orient polyethylene terephthalate). The OPET layer is the foil outer and inner sides of the LDPE layer. The foil is a printed or unprinted. The foil is used in blister packaging and pharmaceutical packaging.

- Description:

The foil is printed or unprinted text matter, it is made structure of aluminium laminated with an LDPE layer on one side and another side laminated with LDPE and OPET layer foil.

2. Text matter:

The sample is printed text matter, and the text matter matches with shade card or artwork

3. Color scheme:

The sample printed text matter color, the text matter color scheme matches with the approved shade card or Pantone card.

4. Width:

The sample testing of the width, the testing of the width measure with the help of measuring scale. The sample testing width and note down it.

5. Inner core diameter:

The sample of the foil is a roll. The roll inner core diameter is tested with the help of a measuring scale. The sample measures the inner core diameter and notes the reading.

6. Grammage:

- Total Grammage:

The sample of OPET/LDPE/Alum/LDPE Foil testing of the total Grammage cut the sample 10 x 10 cm2 or 5 x 5 cm2 (as applicable) with the help of a GSM plate. If the sample is printed the text matter is removed by the cotton or cloth dipped in ethyl acetate rubbing on the text matter the text matter drying the sample at room temperature. Weighing the sample at analytical balance calculation the total Grammage by the given formula

Total Grammage = weight in grams x 100 or 400 (if the sample 10 x 10 cm2 or 5 x 5 cm2)

- OPET Grammage:

The sample of total Grammage dipped in 40% of the glacial acetic-containing glass beaker. Boiling the sample on the hot plate. After some time the OPET layer is separated from the LDPE/Alum/LDPE layer. Washed the sample of OPET Layer with water and dried the in a hot air oven for 2 min at 650c. Cool the sample in a desiccator, weighing the sample at an analytical balance, and calculate the Grammage by the given formula,

OPET Layer Grammage = weight in grams x 100 or 400 (if the sample 10 x 10 cm2 or 5 x 5 cm2)

- LDPE And Aluminium Grammage:

The sample of the remaining LDPE/Alum/LDPE Layer dipped in the ethyl acetate-containing glass beaker. After some time (about 15 min to 20 min) the LDPE layer is separated from the aluminium layer. Wash the sample with water in both layers of LDPE and Aluminium layer. Dry the sample in a hot hot-air oven for 2 minutes at 650c. Cool the sample in a desiccator, weighing the sample at an analytical balance, and calculate the Grammage by the given formula,

LDPE Layer Grammage = weight in grams x 100 or 400 (if the sample 10 x 10 cm2 or 5 x 5 cm2)

Alum Layer Grammage = weight in grams x 100 or 400 (if the sample 10 x 10 cm2 or 5 x 5 cm2)OPET

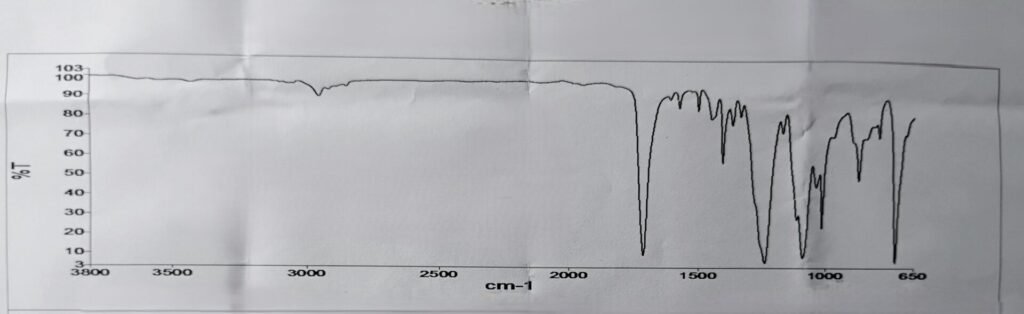

7. Identification by FTIR:

- For PET LAYER:

This test is performed by FTIR instrument, cutting a sufficient sample of The OPET/LDPE/Alum/LDPE Foil is Foil with the PET layer side of the sample. Its standard is PET match with the same wave number. We plotted the spectra with wave number of 3800-650cm-1 standard and sample.

The IR Spectrum of the PET side of the sample matches the IR spectrum of the corresponding working standard.

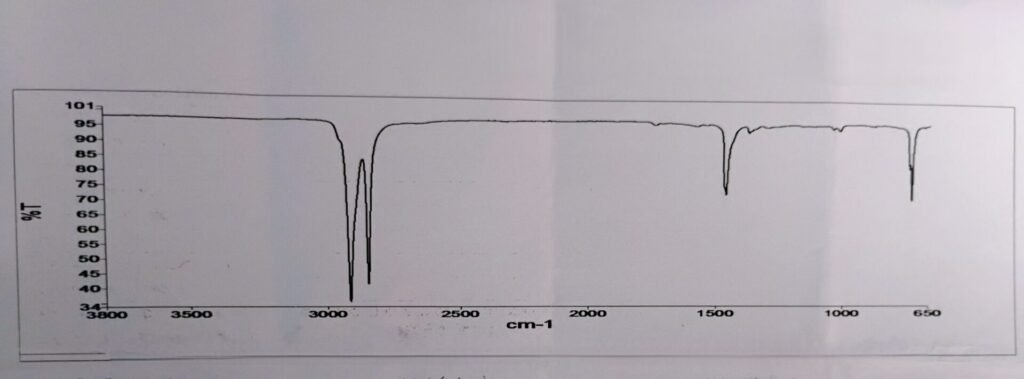

- For LDPE Layer:

This test is performed by FTIR instrument, cutting a sufficient sample of OPET/LDPE/Alum/LDPE Foil with the LDPE layer side of the sample. Its standard is LDPE match with the same wave number. We plotted the spectra with wave number of 3800-650cm-1 standard and sample.

The IR Spectrum of the LDPE side of the sample matches with the IR spectrum of the corresponding working standard.

8. Identification of aluminium by chemical method:

The sample of aluminium Grammage weight 15 mg and put it in a beaker mixing 30ml 1NHCL then heat the beaker aluminium foil to dissolve, in solution add about 1 ml HCL and 1 ml of thioacetamide regents, no precipitate is formed, add dropwise NaoH solution, a gelatinous white precipitate is formed which dissolve on further addition of 1NaoH Solution after gradually addition ammonium hydroxide solution .gelatinous white precipitate is re-formed.

9. Thickness:

- Total thickness:

The sample of OPET/LDPE/Alum/LDPE Foil total thickness with the help of a digital micrometer. The total thickness measuring and note the reading.

- Aluminium thickness:

The sample of aluminium Grammage sample thickness with the help of a digital micrometer. The aluminium thickness measuring and note the reading.

- OPET Layer thickness:

The sample of OPET layer Grammage. The OPET Layer thickness with the help of a digital micrometer. The OPET Layer thickness measuring and note the reading.

- LDPE layer thickness:

The sample of LDPE Grammage sample, the LDPE layer thickness with the help of a digital micrometer. The LDPE layer thickness measuring and note the reading

10. Pinhole testing of OPET/LDPE/Alum/LDPE Foil:

Take the sample of OPET/LDPE/Alum/LDPE Foil test performed by Illuminated magnifier tester instrument. Its instruments are in the background white light. Put the sample on the front of the bench. We neck eye verify the sample. Ensure the sample has no pine holes. It is easily identify the foil is no pinhole.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.