Aluminium foil is a type of primary packaging material. It is directly connected to the drug. It is coated with HSL/VMCH. The other side is printed with different types of ink. Aluminium foil testing depends on which coating type is on the coating side. the testing method was applied according to his coating type on aluminium foil. this foil used as lidding foil

HSL (Heat Seal Lacquer): This is a type of coating applied to aluminum foil to enable heat sealing. It’s used to seal the foil to itself or other materials (such as plastic or paper) in packaging applications. Heat sealing is a common method for closing packages securely.

VMCH (Vinylidene Chloride Vinyl Chloride Copolymer): This VMCH resin type is often used as a barrier coating in aluminum foil laminates. It provides excellent oxygen and moisture barrier properties, making it suitable for packaging applications where protection against these elements is crucial. VMCH coatings help extend product shelf life by preventing spoilage caused by oxygen and moisture.

Here are some Aluminium Foil testing method parameters we discussed

Table of Contents

1. Description:

we physically verify whether aluminum foil is printed or unprinted. Types of coating HSL or VMCH coating. In printed aluminium foil visually check the test matter is printed without any bladdering is required. Printed aluminium foil is visible at the eye point. the thin aluminium layer is laminated with HSL(heat seal lacquer) or VMCH ( vinyl chloride,vinyl chloride, vinyl acetate, and Maleic Acid).

2. Text matter:

Test matter is compared with a standard shade card or artwork, In this testing the quality of the print inspection of aluminium foil. The printed foil is printed with different Pantone color text matter.

3. Color Scheme:

The aluminium foil is printed then, testing the text matter of the color scheme match with the shade card or Pantone card

4. Width:

The aluminium foil tests the foil width with the help of a measuring scale. the selected sample measure the width and note the reading.

5. Inner core diameter:

the aluminium foil is in a roll form. The roll’s inner core diameter can be tested with the help of a measuring scale. take the reading of the selected sample and note down the reading.

6. Identification of aluminium:

- chemical method

The chemical method of aluminium foil take the sample Weight the aluminium foil 15 mg sample put it in a beaker mix 30ml 1NHCL then heat it on the hot plate. the beaker aluminium foil to dissolve, in solution, add about 0.5 ml conc HCL and thioacetamide regents, no precipitate is formed, add dropwise NaoH solution and a gelatinous white precipitate is formed which dissolves on further addition of 1NaoH Solution after gradually addition ammonium hydroxide solution .gelatinous white precipitate is re-formed.

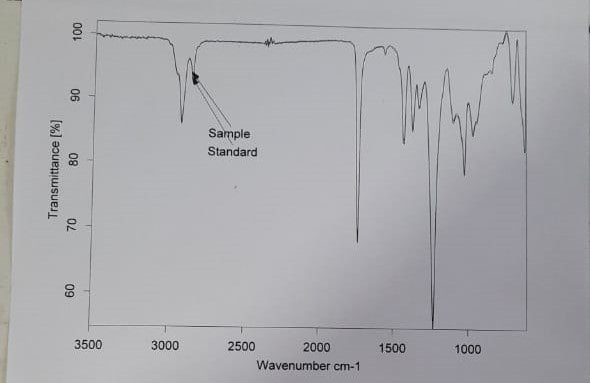

- IDENTIFICATION BY FTIR:

The identification test of the Foil Sample, this testing is performed with the help of the FTIR Instrument. In this foil identification test HSL Layer, first of fall, we platted the graph of Zeon reference standard, then after scanning the sample of HSL Layer sample. Both reference standards and the HSL Layer sample plotted the graph at 3800-650 cm-1 by the FTIR Instrument.

The spectrum of the specimen exhibits major absorption bands only at the same wavelength as the spectrum of the HSL Layer sample and Zeon reference standard.

7. Grammage:

- Total Grammage:

The sample of Aluminium foil of Grammage testing is performed, cut the sample 10 x10 cm or 5 x 5 cm with the help of a GSM Plate. For printing foil with a cotton Rubbing mix of ethyl acetate on the printed side, carefully not contact with the coating side. Dry at room temperature. And then weighing the sample at analytical balance, the Grammage calculation by the given formula

Total Grammage = weight in grams x 100 or 400 (if the sample cut 10 x 10 cm or 5 x 5 cm)

- For Aluminium Layer:

The sample of total Grammage was completely dipped in a glass beaker containing ethyl acetate. After some time with a cotton Rubbing mix of ethyl acetate on the coating side. The aluminium layer is separated from the aluminium. Dry room temperature the aluminium layer, the weight of the sample weight on an analytical balance calculated the Grammage by the given formula,

Aluminium layer Grammage = weight in grams x 100 or 400 (if the sample cut 10 x 10 cm or 5 x 5 cm)

- For HSL/VMCH Layer

HSL/VMCH Layer = Total Grammage- Aluminium layer Grammage

8. Thickness:

The aluminium layer takes the sample of the “aluminium layer grammage”. measure the thickness of the aluminium layer with the help of a digital micrometer. take the reading of the aluminium layer and note down the reading.

9. Pinhole test for aluminium foil

The pinhole testing of the sample of Aluminium foil testing foil of illuminated magnifier tester instrument. When the sample is put on the bench of the pinhole tester, the background light is identified as the hole in the Foil sample. It visually checks the sample and does not have any holes. The test identified that the sample had no holes.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] more information about to full testing of VMCH/HSL Coated aluminium foil […]

[…] The aluminium layer from the sample 15 mg of aluminium layer in a glass 200 ml beaker. Put in 30 ml of 1 N HCL Beaker. Heat the solution till aluminium dissolves in that solution add about 1 ml of hydrochloric acid and 1 ml of thioacetamide regent. No precipitate is formed. Add drop-wise 1N NaOH Solution. A gelatinous white precipitate is formed. Which dissolves on further addition of 1N Sodium hydroxide solution after gradually addition of ammonium hydroxide solution gelatinous white precipitate is re-formed […]

[…] sample of the combination of layer-oriented polyamide-aluminum-heat Seal Lacquer layer cut 10 x 10 cm or 5 x 5 cm with the help of a GSM plate, then weighed an analytical […]

[…] in a hot air oven for 5 minutes in both layers. Then cool at room temperature. Take the weight of the aluminium layer and PVC layer and record the […]

[…] Aluminium foil is used to pack pharmaceutical finished products in Alu-Alu and blister packing, cold-form packaging. Aluminium foil sealing with PVC or cold-form foil aluminium foil requires an adhesive. The adhesives are LDPE, Heat seal lacquer, and VMCH. When the heat is provided, the adhesive is sealed to aluminium foil to rigid PVC, cold form, or other rigid layer. […]

[…] LDPE layer dissolved and the aluminium layer dried at room temperature for 5 min After drying the aluminium layer then take weigh […]

[…] sample of the combination of layer Glassine Paper/Alum foil/Nat Foil cut 10 x 10 cm or 5 x 5 cm with the help of a GSM plate, then weigh an analytical […]

[…] sample of HSL/Alum/Paper foil cut the sample 10 x 10 cm or 5 x 5 cm with the help of a GSM plate, take the weight […]

[…] Aluminium foil is a thin-rolled sheet of allotted aluminium varying in thickness found about 4-150 μm. Aluminium has excellent physical protection and barrier properties, formability and decorative potential, recyclability and consumer acceptance, making it one of the most common metal-based packing materials. […]

[…] seal foil: a thin layer of aluminium foil with a heat-sealable coating like coating HSL, VMCH. Its foil is designed to bond with various […]

[…] The child-resistant lidding foil is a combination structure of Paper-polyethylene terephthalate-aluminium-heat seal Lacquer. It is made four-layer structure of […]

[…] is multi-layered combining paper, aluminium, and a heat seal lacquer, this type of material is often used in blister packs for pills, sachets, or other forms of […]

[…] laminated PET Foil is made from a thin aluminium foil coated with PET (polyethylene terephthalate). Laminating aluminum with PET foil involves bonding these two […]

[…] other side coated with an HSL layer. Its foil is made with three layers of OPA (Orinated polyamide) aluminium layer, and HSL (Heat seal lacquers). It is a multi-structure layer foil. It foil is packaging the […]

[…] The aluminium foil is laminated with OPA (oriented polyamide). One side is printed, the other is plain, or both are plain unprinted foil. […]

[…] thin PVDC layer is laminated with the PVC layer on one side, and the other is laminated with an Alum layer, on the aluminium layer side printed foil or […]

[…] sample of PVC/PE/PVDC/Alum foil is printed, and its printing text matter color scheme matches the shade card or Pantone […]

[…] Alum/PVDC Foil is made from PVDC and aluminum. It foil is made of a thin layer of aluminium laminated with PVDC. The aluminium layer packaging for its excellent barrier properties. It protects against […]

[…] foil structure is made of aclar and is laminated with the PVC and another side is laminated with an aluminium layer. The foil is triplex. The foil is made for packaging pharmaceutical products […]

[…] Alum/Aclar foil sample is made from a thin layer aluminium layer laminated with an Aclar layer. It is printed or unprinted foil, the printed-on aluminium layer. The Aclar […]

[…] Alum/PET foil is made of the aluminium layer laminated with a PET (Polyethylene terephthalate) layer. It is two types of foil printed and unprinted. The […]

[…] Alum/PP foil is made from the aluminium layer laminated with a PP (polypropylene) layer. It is foil two-type printed or unprinted foil, the printing text […]

[…] Alum/PVC foil is made from a thin aluminium layer laminated with PVC (polyvinyl chloride). it foil is lidding foil. There are two types of foil printed and […]

[…] foil is a sample made from PVC (Polyvinyl chloride), PVDC (Polyvinylidene chloride), and aluminium foil. It foils made of a structure PVDC Layer laminated with a PVC layer on one side and the other side […]