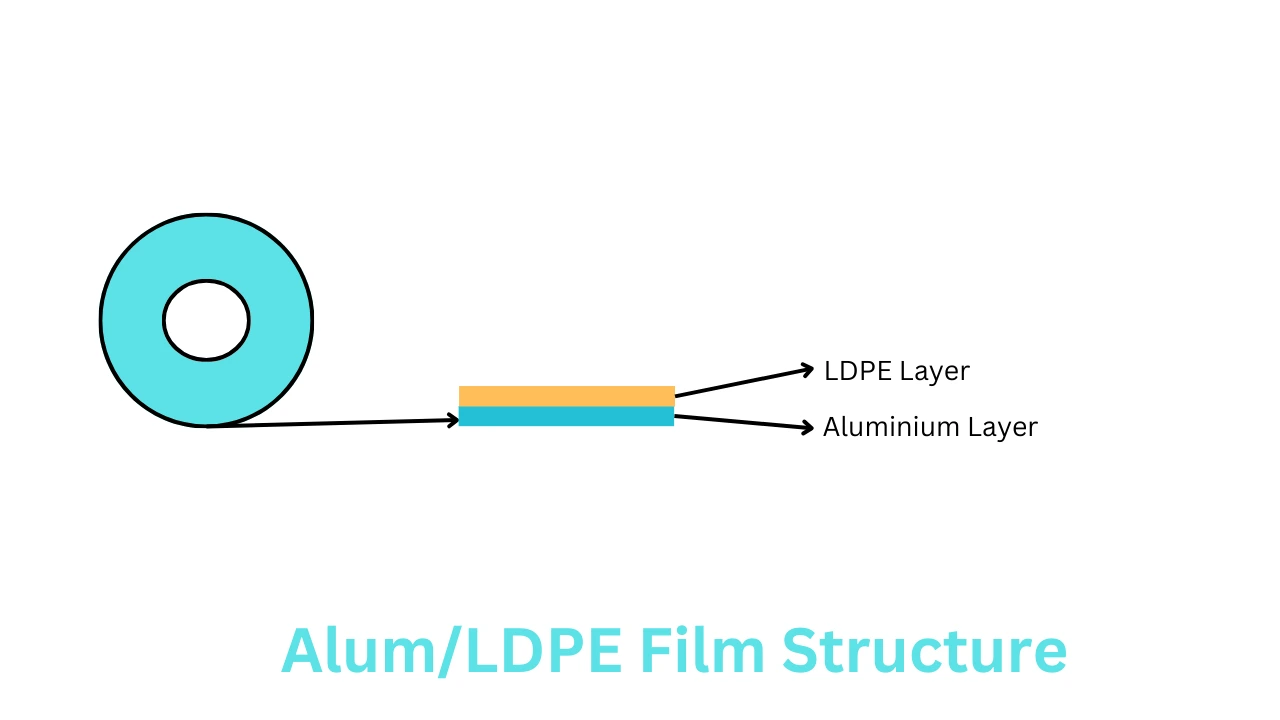

LDPE-Laminated aluminium foil is a type of primary packaging material. It is a Low-density polyethene layer laminated with foil. It is used in the pharmaceutical industry in strip packaging, pouches, sachets, lids, and warps. This type foil made-strip packaging is child-proof. This foil is required where the products are tightly sealed and then the product airs tightly after protection from moisture.

This type of foil is 90% recycled. This foil is easy to recycle. So it is called eco-friendly aluminium foil. Which type are packaging this foil is also called unit dose packaging. It is close to two webs of heat-sealable flexible film. Flexible film made from LDPE.

So this foil has a very critical role in packaging, foil is a good quality used in packaging, and we ensure. Its quality is better.

Here are some test parameters we discuss

- Description: low-density polyethylene aluminium foil are two types printed foil and unprinted aluminium foil. Printed foil of text matter we physically verify no smudging and no test blundering. Printing foil also verifies the eye point.

2. Test matter & colour: if the foil is printed then test matter is compared with a standard shade card or artwork.

3. Width: measure the aluminium foil width help of a calibrated measuring scale.

4. Inner core diameter: measuring inner core diameter by calibrated measuring scale

5. Identification of aluminium:

- chemical method

Weight the aluminium layer 15 mg sample and put it in a beaker mixing 30ml 1NHCL then heat the beaker aluminium foil to dissolve, in solution add about 1 ml HCL and 1 ml of thioacetamide regents, no precipitate is formed, add dropwise NaoH solution, a gelatinous white precipitate is formed which dissolve on further addition of 1NaoH Solution after gradually addition ammonium hydroxide solution .gelatinous white precipitate is re-formed.

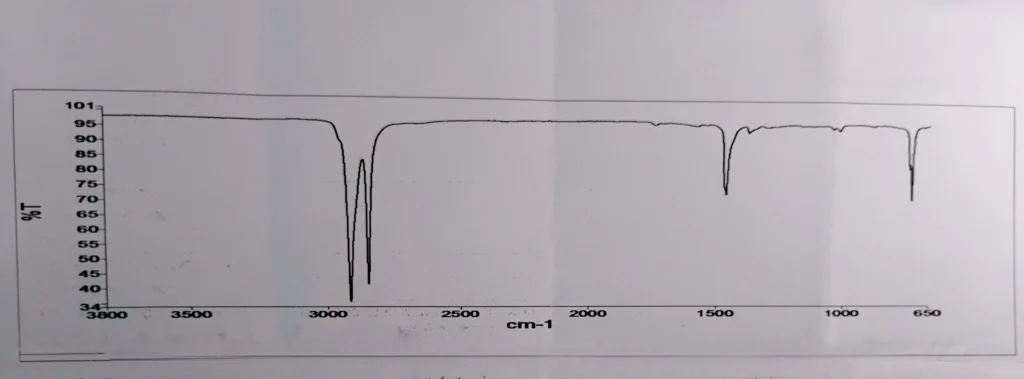

- IDENTIFICATION BY FTIR

This test is performed by FTIR instrument, LDPE-laminated aluminium foil is in contact with the drug so the contact layer is ldpe then we identification test performed with LDPE.

Its standard is LDPE match with the same wave number. We plotted the spectra is wave number is 3800-650cm-1 standard and test

FTIR Graph of LDPE

6. Grammage:

- Total Grammage:

The sample of LDPE-laminated aluminium foil. Cut the sample 10×10 cm2 or 5 x 5 cm2 area (as applicable) with the help of a GSM plate. if the sample is printed, the remove text matter with the help of, the cotton dip in ethyl acetate rubbing on the text matter, after removing the text matter, dry the sample at room temp. Then the sample wt. on analytical balance the calculate the Grammage by the given formula,

Total Grammage= Weight of sample in gram x 100 or 400(if the sample cut the 10 x 10 or 5 x 5 cm2)

- Alum. Layer Grammage:

The sample of total Grammage was taken, and the sample dipped in a toluene-containing beaker. Heat the sample on a hot plate the samples, the LDPE layer is dissolved in the solution. the remaining sample is an aluminium layer. The Aluminium layer is dry at room temperature. Then taken wt. of aluminium layer wt. at analytical balance. Grammage calculation by the given formula

Alum of Grammage = Weight of sample in gram x 100 or 400 (if the sample cut the 10 x 10 or 5 x 5 cm2

- Grammage of LDPE Layer:

Grammage of the LDPE layer is by the given formula,

LDPE Grammage = total Grammage – Alum. Grammage

7. Thickness: the measurement of the total thickness of aluminium foil with the help of a calibrated digital micrometer. It also measured the total thickness of the aluminium layer taking the sample of GSM testing to separate the layer from LDPE. Take reading record it.

8. Pin hole: take the sample of aluminium foil test performed by Illuminated magnifier tester instrument. Its instruments are in the background white light. Put the sample on the front. We neck eye verify the sample. Ensure the sample has no pine hole

[…] It is two types printed and unprinted the printing text matter is on the OPA layer side and the LDPE layer is the inner side of the foil. This foil is used as a pharmaceutical finished bulk product. The […]

[…] selected sample of LDPE Laminated foil cut the sample 10 x 10 cm2 or 5 x 5 cm2 area (as applicable) with the help of a GSM Plate. At […]

[…] OPET/LDPE/Alum/LDPE Foil is made from the structure of the aluminium layer. It is laminated with LDPE (Low-density polyethylene) on one side and on the other side, an LDPE layer with an OPET (Orient […]