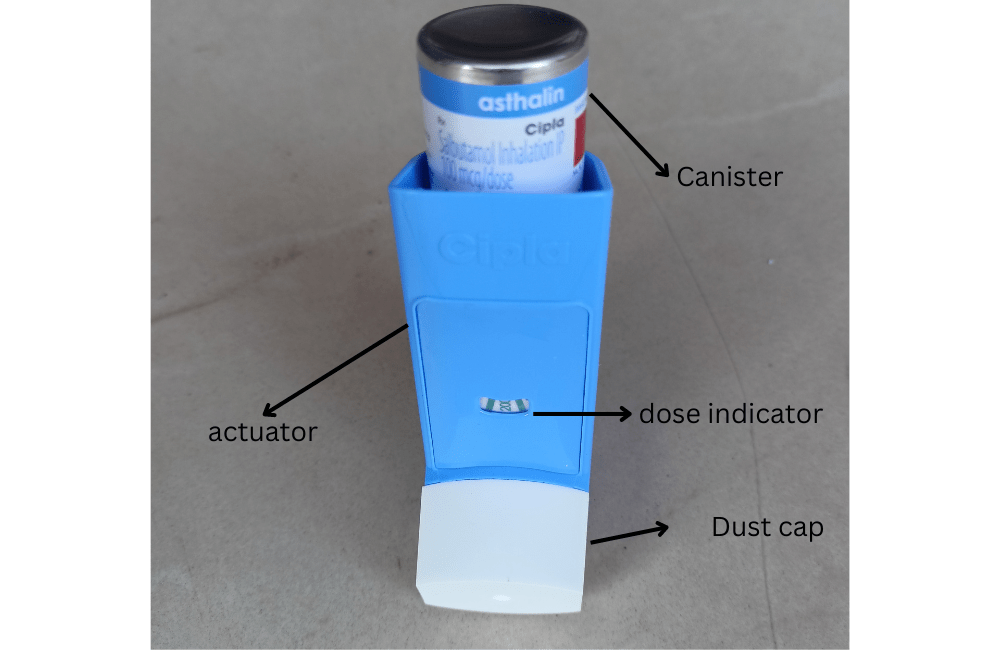

The actuator is directly connected to drugs so, it is the primary packaging type material. inhaler packaging of the actuator is used in meter dose inhalers. It has three parts, a canister, a metering valve, and an actuator. The meter-dose inhaler actuator for pressurized aerosol containing a formulation of at least one medicament in a liquefied propellant gas.

It is made from polyethylene or polypropylene material. Its samples are connected to the mouthpiece. It is protected from other contamination. Its body and cap have a joint angle of 1200. It has many different colors. The sample has an orifice with diameters are 0.14 mm to 0.6 mm. It plays an important role in MDI.

The actuators contain components are,

- A Nozzle block having a bore to receive a valve stem

- A sump in connection with a bore, where the propellant formulation expands upon the actuation of the inhaler

- A nozzle channel, existing from the sum and aligned with a mouthpiece.

So, the actuators plays an important role produce a meter-dose inhaler. The quality is better than we follow some testing procedures

1. Description

14 ml or another type of 10ml, 19ml polypropylene actuator orifice type of color cap and body

2. Dimension

- Length: Select 5 samples in stock sample measure sample length with a calibrated Vernier caliper. One by one take the reading and note down the reading

- Width: Select 5 samples in stock sample measure sample width with a calibrated Vernier caliper. One by one take the reading and note down the reading

- Valve stem receptacle: Select 5 samples in stock to measure actuator width with a Calibrated Vernier caliper. One by one take the reading and note down the reading

- Spray orifice diameter: Select 5 samples in the stock sample. Broken the actuators and took the spray orifice. Measure the actuator Spray orifice diameter with a calibrated Vernier caliper. One by one take the reading and note down the reading

Dust cap

- Height: Select 5 samples in the stock sample. Measure the sample dust cap height diameter with a calibrated Vernier caliper. One by one take the reading and note down the reading

- Width side to side: Select 5 samples in the stock sample. Measure the sample dust cap width side-to-side diameter with a calibrated Vernier caliper. One by one take the reading and note down the reading

- Width front to back: Select 5 samples in the stock sample. Measure the actuator dust cap width front to back diameter with a calibrated Vernier caliper. One by one take the reading and note down the reading

4. Number of doses (declaration)

Select 5 samples in the stock sample. Visually check how many number of dose indicators show on the actuator ex. 120 ,180, or other

5. Number of doses:

Select 5 samples in the stock sample connected with a propellant canister. Actuate (spray) the sample and count the dose according to the spray then indicate the color change meter dose. Then endpoint the color is green to red or given color change according to dose. The number of doses (declaration) found the dose in the actuator.

6. Fitment performed with spacer

Select 5 samples in the stock sample. The sample should work properly with the spacer the actuator mouthpiece should go inside the spacer smoothly the fitting should not fail by itself on shaking the spacer.

7. Fitment performance with cap

Select 5 samples in the stock sample. The actuator body should fit perfectly with CFC a free dust cap.

8. Check for contamination

They should be free from deformity, heavy scratches, dust, and foreign particles inside the actuator. glaring color difference smeared printing and free from any other contamination

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] a filled aerosol canister along with an actuator and dust […]

[…] valve). it is a complete set connected to the actuator. meter dose inhaler is divided into parts the actuator, canister, and meter […]