PVC PVDC Film is a type of primary packaging material. PVC (polyvinyl chloride) Foil with a PVDC (polyvinylidene chloride) coating is often used for high-performance packaging film like pharmaceutical blister packs. the PVC/PVDC film for pharmaceutical packaging.

Which protects pharmaceuticals against oxygen and odor, moisture, water vapor transmission contamination, and bacteria. These properties make PVC/PVDC the material of choice for blister packaging. the blister packaging also required to lidding foil. the lidding foil is used to blister packaging.

PVDC-coated PVC film has excellent barrier properties against moisture water vapor, UV light aroma, inorganic acids, alkalis aqueous salt solution, organic water-soluble acids, aliphatic hydrocarbon, ester of long chain fatty acid, detergent base materials, emulsifying agent and wetting agent.

PVDC Packaging is About 67% of blister packaging uses PVDC Film Composition film. PVDC is a heavy-barrier polymer material. It has the characteristics of flame resistance corrosion resistance and good air tightness due to strong polarity. PVDC is insoluble in oil and organic solvents and soluble in polar solvents.

So, it has an important role in pharmaceutical packaging. Its quality is also better than following some testing procedures,

Table of Contents

1. Description

A Clear transparent or colored rigid PVC film coated with PVDC.

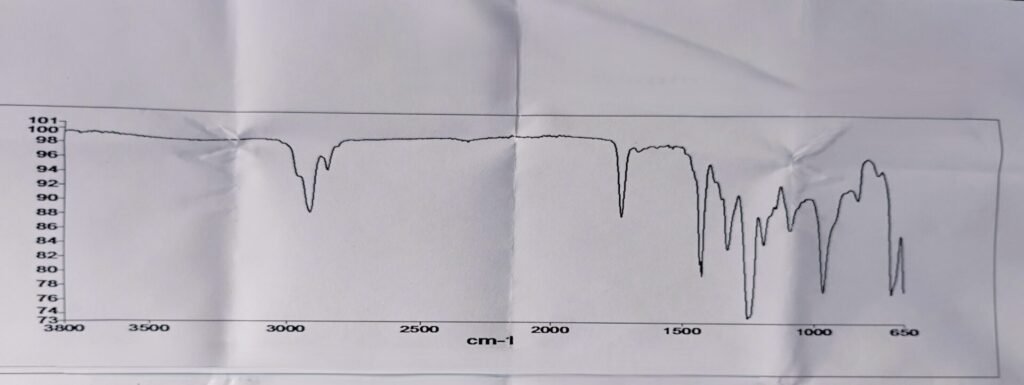

2. PVC And PVDC Identification Test by FTIR

Identification of PVC: This test is performed by FTIR instrument, cutting a sufficient sample of PVC/PVDC foil and taking the PVC side of the sample. Its standard is PVC match with the same wave number. We plotted the spectra with wave number of 3800-650cm-1 standard and sample.

The IR Spectrum of the PVC side of the sample matches with the IR spectrum of the corresponding working standard.

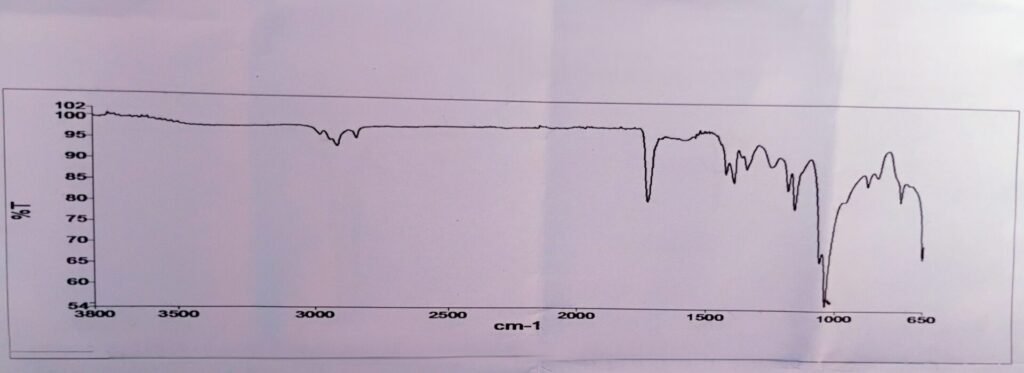

Identification of PVDC: This test is performed by FTIR instrument, cutting a sufficient sample of PVC/PVDC foil and taking the PVDC side of the sample. Its standard is PVDC match with the same wave number. We plotted the spectra with wave number 3800-650cm-1 standard and sample.

The IR Spectrum of the PVDC side of the sample matches with the IR spectrum of the corresponding working standard.

3. Width

selected sample from the stock. Measure the width with the help of a measuring scale. Take the reading and note down the reading.

4. Grammage test of PVC/PVDC Film

Total Grammage:

the sample of PVC/PVDC film total grammage testing selected the 5 samples at different positions and cut the sample 10 x 10 cm or 5 x 5 cm(as applicable) with the help of GSM Plate. Weight the sample at a calibrated analytical balance. Record the weight. calculated the total grammage by the given formula,

Total Grammage = Weight of sample in gram x 100 or 400 (if the sample is cut 10 x 10 cm or 5 x 5 cm)

Grammage of PVDC:

- Take the total Grammage sample and completely dip it in acetone for 5 to 10 min. check intermittency whether the PVDC layer is separating or not

- The PVDC layer will be separated and dried in a hot air oven 1050c for 5 min cool it and take the weight at analytical balance

Grammage of PVDC = Weight in grams x 100 or 400 (if the sample 10 x 10 cm or 5 x 5 cm)

Grammage of PVC: the PVC layer will absorb the solvent and swell and hence it will not be accurate to calculate the GSM. So we calculate the GSM of PVC with the help of the total of Grammage and Grammage of PVDC.

Grammage of PVC= Total Grammage- Grammage of PVDC

5. Core Internal Diameter

Selected the sample role to measure the core internal diameter with the help of measuring tape or measuring scale. Its limit is 75-77 mm

6. Thickness of film

Total Thickness Film: selected 5 samples in stock and measured the Total thickness with the help of a calibrated digital micrometer. Take reading and note it.

The thickness of PVDC film: selected the sample from Grammage of PVDC. Measured the sample with the help of a calibrated digital micrometer. Take a reading and record it.

7. Morpholine test for PVDC

taken selected sample in stock. Take morphine regent in a dropper. It drops out on both sides of a sample.

On one side will turn yellowish to brownish after a few seconds. Its side is called PVdC.

8. Vinyl Chloride Residue Monomer:

The Vinyl chloride monomer is a dangerous substance in terms of flammability and reactivity. It can be distributed and handled safely. It is the intermediate raw material. It has a boiling point 13.90 c and a freezing point -780 c.

A known amount of unreacted vinyl chloride monomer can be found in PVC. But their concentration is so low that processing and use of PVC, products is perfectly safe.

Its limit is NMT 1ppm

9. Toxicity:

When The Vinyl Chloride Monomer Can be found in PVC in the manufacturing process when its limit is NMT 1PPM then it is non-toxic. When its limit is greater than 1ppm its foil is toxic.

Mainly in pharmaceutical PVC/PVDC foil used food grade and it is non-toxic

10. Pinhole:

selected the sample in a lot. The sample put on the platform of the pinhole tester sample visually checked with the help of background light. It’s no hole appears on the surface of the sample.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] PVC Film- Packaging Material Standard Testing procedure […]

[…] If more information how full testing of PVC/PVDC Foil of packaging materials […]

[…] A Clear transparent or color rigid PVC film coated with PVDC and PE layer is sandwiched between PVC and PVDC […]

[…] packaging material. Its foil combines aluminum foil between nylon (OPA) OR Polyester (PET), PVC, or PVC/PVDC layers. Its foil is also called cold-formed blister […]

[…] of PVC blister packages by a factor of 5-10. It combination in product packaging of layers of PVC/PVDC, […]

[…] sample PVC/PVDC/Alum foil is printed text matter, the printed text matter matches the shade card or […]

[…] times without any loss of technical property. PVC has the lowest environmental impact compared to PVC/PVDC and […]

[…] PVC/PVDC/Alum foil is a sample made from PVC (Polyvinyl chloride), PVDC (Polyvinylidene chloride), and aluminium foil. It foils made of a structure PVDC Layer laminated […]