A laminated tube is a type of primary packaging material. Laminate Tubes for Pharma are manufactured in multilayered foil using aluminium or plastic barriers that are inserted between the inner and outer layers of the tube. They are the two most commonly used materials for barrier properties aluminium or ethylene vinyl alcohol (EVOH).

Laminated Tube

They are a common type of laminated tube base of barrier properties material in use, Aluminium barrier laminated (ABL), Plastic barrier laminated tube (PBL), and Co-extruded tubes.

Lami tubes are divided into three parts, tube head, tube body, and tube cap. There are different types of materials in use. The composition of the material is 50% to 60% (w/w) of high-density polyethylene (HDPE), 30 % to 40% (w/w) of ethylene alcohol (EVOH), and 10 to 20% (w/w) of at least one compatibilizer, wherein the compatibilizer is selected from an ionomer or a maleic or a maleic anhydride copolymer used.

His properties by the making the product more reliable, smooth, and flexible, with puncture resistance, moisture resistance, and high filling line speed. The tube has a wide range of caps/closures use flip-tops, stand-up caps,

This type of tube is more popular because it is very attractive and reliable packaging. And they are hygienic, lightweight, and toxin free which helps to improve the shelf-life of the product.

So, they are important products in packaging material, the material also ensures the quality of following bellow laminated tube testing parameters,

Table of Contents

1. Description

Printed or unprinted laminated tube (type tube material) with the type of cap used.

2. Identification

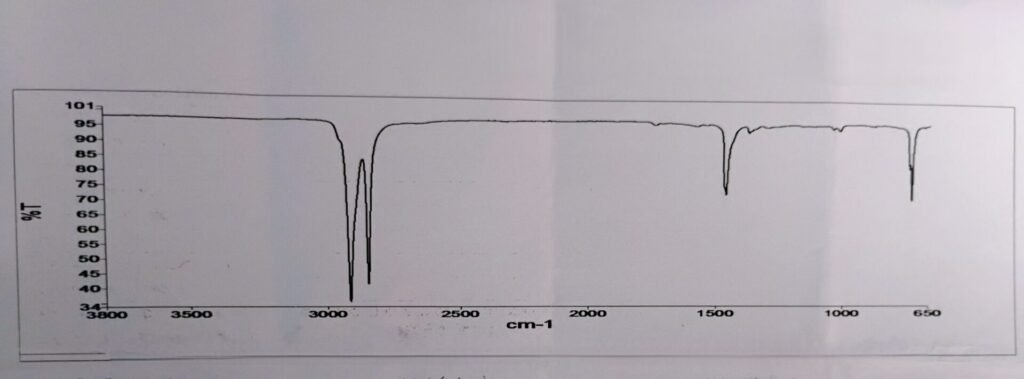

Identification of LDPE Tube Material (body): The laminated tube is made from polymer their polymer is made single polymer or mixed polymer they are identified by the multiple internal reflectance. Its test is performed by the FTIR instrument. This Laminated tube (body) is made from LDPE. The standard is the LDPE Reference standard. The standard is a graph plotted between the wavelength 3800-650 cm-1. The sample is also plotted 3800-650 cm-1.

The IR Spectrum of the LDPE side of the sample matches with the IR spectrum of the corresponding working standard.

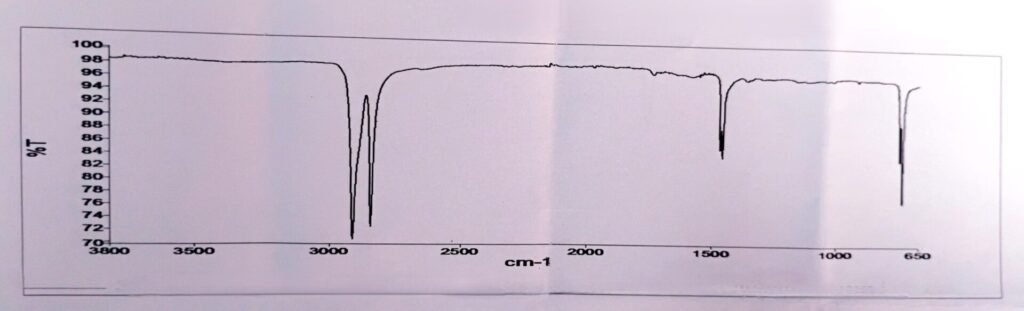

Identification of HDPE Tube Head:

The standard is the HDPE Reference standard. The standard is a graph plotted between the wavelength 3800-650 cm-1. The sample is also plotted 3800-650 cm-1.

The IR Spectrum of the HDPE side of the sample matches with the IR spectrum of the corresponding working standard.

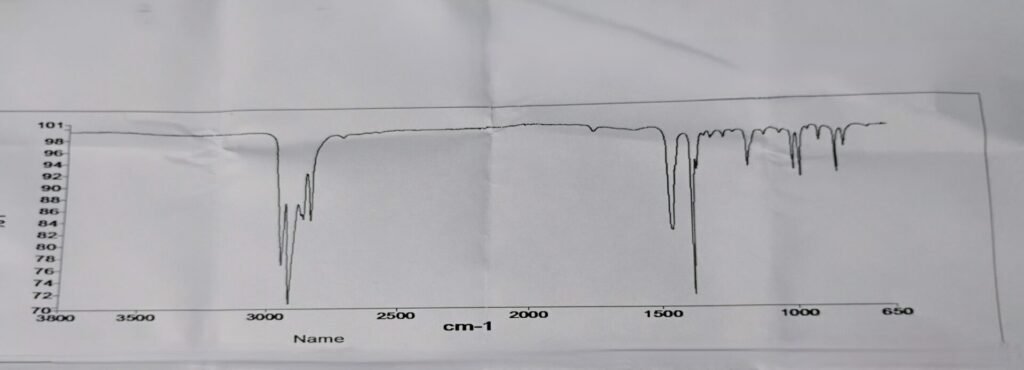

Identification of (CRC CAP) PP:

The standard is the PP Reference standard. The standard is a graph plotted between the wavelength 3800-650 cm-1. The sample is also plotted 3800-650 cm-1.

The IR Spectrum of the PP side of the sample matches with the IR spectrum of the corresponding working standard.

3. Tube Dimension

Tube diameter: select the random sample from stock and measure the tube diameter with the help of a Vernier caliper, take readings one by one and note the reading.

Tube Length from shoulder: select the random sample from stock and measure the tube length from the shoulder with the help of a Vernier caliper, take readings one by one and note the reading.

Wall thickness: select the random sample from stock and measure the tube Wall thickness with the help of a Vernier caliper, take readings one by one, and note the reading.

Tube orifice inner diameter with a top seal: select the random sample from stock and measure the tube Orifice inner diameter with a top seal with the help of a Vernier caliper, take readings one by one, and note the reading.

Seam over cap: select the random sample from stock and measure the tube seam over the cap with the help of a Vernier caliper, take readings one by one, and note the reading.

Tube weight with cap: select the random sample from stock and the tube weight with the help of calibrated an analytical balance one by one weight record the reading.

CAP

CAP Height: select the random sample from stock and measure the cap height with the help of a Vernier caliper, take readings one by one, and note the reading.

Cap diameter: select the random sample from stock and measure the cap diameter with the help of a Vernier caliper, take readings one by one, and note the reading.

Bottom diameter: select the random sample from stock and measure the bottom diameter with the help of a Vernier caliper, take readings one by one, and note the reading.

Thread internal diameter: select the random sample from stock and measure the thread internal diameter with the help of a Vernier caliper, take readings one by one, and note the reading.

4. Wop polyethylene

A) Method of separation of Laminated tube (WOP LAYER)

- Take a laminated tube cut sample 5 x 5

- Dip a sample in Glacial acetic acid 99% boil with the sample for 20-30 min immerse the sample in 4-layer and 2 and 3 layers are separated

- Dip the coex film in toluene and boil the coex film to dissolve

- Clean the remaining WOP Polyethylene for 2 min

Measure the digital micrometer of thickness separate layer

B) Method of delamination of Laminated tube

- Take a sample and cut a rectangular/square sample

- Immerse it in a 100 ml solution of 50% glacial acetic acid + 50% water

- Heat it at 700c till it starts boiling and later delamination ( 11-15 min)

- Take out the sample and completely delaminate the partial delaminate sample using a cutter or sample sharp instrument which can go between the layers.

Measure the digital micrometer of thickness separate layer

5. Text matter

if the laminated tube is printed then the text matter compares with the shade card or artwork for other languages compared with trenchancy.

6. Color scheme

take the sample for color scheme compared with the shade card or Pantone card

7. Check for contamination

free from deformity and heavy scratches, dust, dirt, foreign particles inside, the tube glaring color difference smeared printing, and free from any leakage

8. Bio burden of the test by membrane filtration method

Total bacterial count: not more than 50cfu/10 units

Total fungal count: not more than 5 cfu/10 units

9. Light transmission

Take the Laminated tube cut by the cutter of a suitable size. Wash and dry taking care to avoid leaving fingerprints or other marks on the surface area of the sample through which light must pass.

In the UV instrument set spectrophotometer mode wavelength 290 to 450 nm. First blank scan at wavelength 290 to 450 nm the reading 100% light pass. Then the sample is placed in the sample cabinet scan the sample is capable of measuring and recording light transmitted diffused as well as parallel rays.

10. Bar code

this test is performed with the help of a shade card or artwork. The sample is compared with the standard specimen, shade card or artwork.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] bioburden membrane filtration method is a microbiology test. the packaging material is a Laminate tube and aluminum tube. it is suitable for finishing products, bacterial growth, or fungal […]

На этом сайте вы можете приобрести изделия бренда Loro Piana. Каталог товаров включает роскошные изделия, производимые с применением высококачественных материалов и современных технологий. Познакомьтесь с атмосферу стиля и комфорта, который предлагает итальянский дом Loro Piana.

https://loropiana.whitezorro.ru