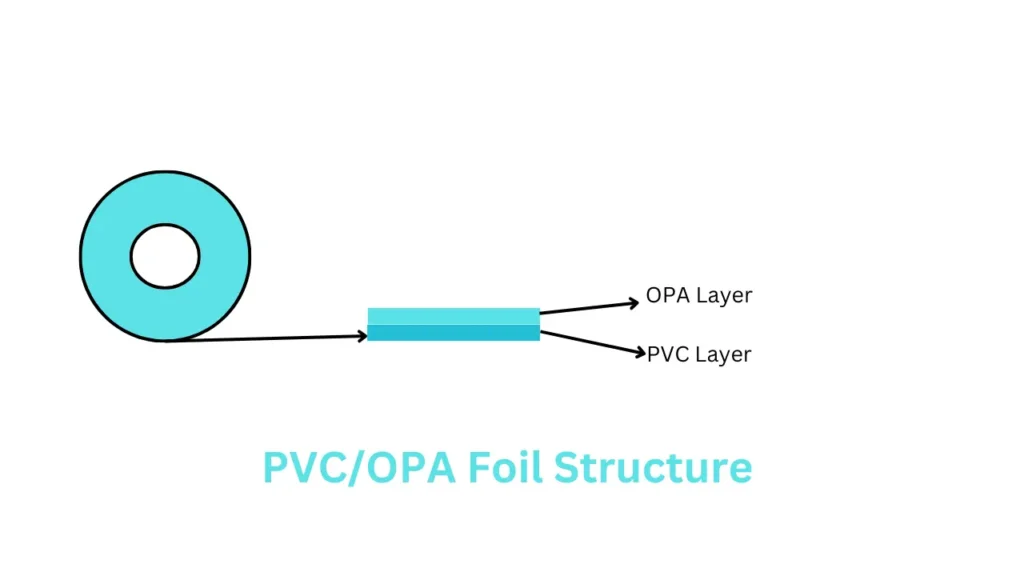

PVC/OPA Foil makes the PVC (Polyvinyl chloride) with a laminated OPA (orinated polyamide) layer. A PVC Layer is a common plastic material that provides strength and rigidity. It serves as the main structural layer, offering protection against physical damage. The OPA is also known as nylon, OPA is used as a barrier layer that adds toughness, and puncture resistance and acts as a barrier to gases and moisture

The PVC/OPA combination protects sensitive products like pharmaceuticals, ensuring they are shielded from environmental factors such as light, moisture, and oxygen. It is commonly used in blister packs for medicines, ensuring long-term stability and quality of the packaged drugs.

1.Description:

A thin layer of PVC (polyvinyl chloride) is laminated with an OPA layer (originated polyamide). It has two foil types printed and unprinted.

2.Text matter:

The foil PVC/OPA foil is printed to match with text matter shade card or artwork.

3. Color scheme:

The foil PVC/OPA sample printed color scheme text matter matches with the shade card or Pantone card.

4. Width:

The sample of PVC/OPA foil measured width with the help of a measuring scale. Measure the samples one by one and note the reading.

5. Inner core diameter:

The sample is in roll form the inner core diameter measures the measuring scale, and the sample roll measures the roll and notes down.

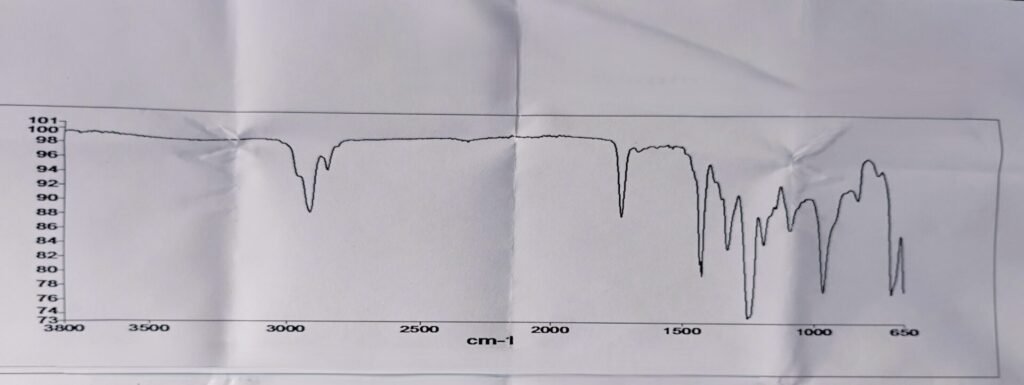

6. The PVC layer of Identification by FTIR:

The identification of the sample of PVC/OPA Foil is done by identification testing performed with the help of an instrument by FTIR. The sample of the PVC side layer identifies its instrument. Its sample compares the sample of the PVC Layer reference standard. We take the PVC Reference Standard and the sample of the PVC Layer side. Its graph is plotted at a wavelength of 3800-650cm-1.

The spectrum obtained from the specimen exhibits major absorption bands only at the same wavelengths as the spectrum of the PVC reference standard.

7. Grammage:

- Total Grammage:

The total Grammage sample of PVC/OPA foil testing with the help of 10 x 10 cm or 5 x 5 cm cut the sample. The sample weight is the analytical balance calculated by the Grammage given formula,

Total Grammage = weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

- For the PVC Layer;

The sample of total Grammage sample dipped in ethyl acetate in the glass beaker, and after some time both layers were separated from each other. The PVC Layer and OPA layer dry the sample in a hot air oven at 700c for 2 min. cool the sample and take weight at analytical balance. Grammage calculation by the given formula,

PVC Layer Grammage = weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

OPA layer Grammage = weight in grams x 100 or 400 (if the sample 10 x 10 or 5 x 5 cm)

8. Thickness

- Total thickness:

The sample of PVC/OPA Foil measures the total thickness with the digital micrometer. The sample reading and taken and noted down.

- PVC Layer:

The sample of PVC layer of Grammage testing, Foil measuring the total thickness with the digital micrometer. The sample measures the reading and takes notes on it.

- OPA Layer:

The sample of OPA layer of Grammage testing, Foil measuring the total thickness with the digital micrometer. The sample measures the reading and takes notes on it.

9. Pinhole

The pinhole testing of the sample of PVC/OPA foil testing foil of illuminated magnifier tester instrument. When the sample is put on the bench of the pinhole tester. The background light is identified as the hole in the Foil sample. It visually checks the sample and does not have any holes. It test identified the sample has no holes.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] the PVC/OPA Foil is made from PVC (Polyvinyl Chloride) and OPA (Oriented Polyamide, also known as Nylon) combination foil is a multi-layered packaging material that combines the unique properties of each material to create a versatile and durable foil for various applications. it foil is used in lidding foil. It provides excellent protection from moisture, gas, and other external factors, extending the product’s shelf life. It also provides enhanced resistance to punctures and tears, providing secure storage and transport. […]