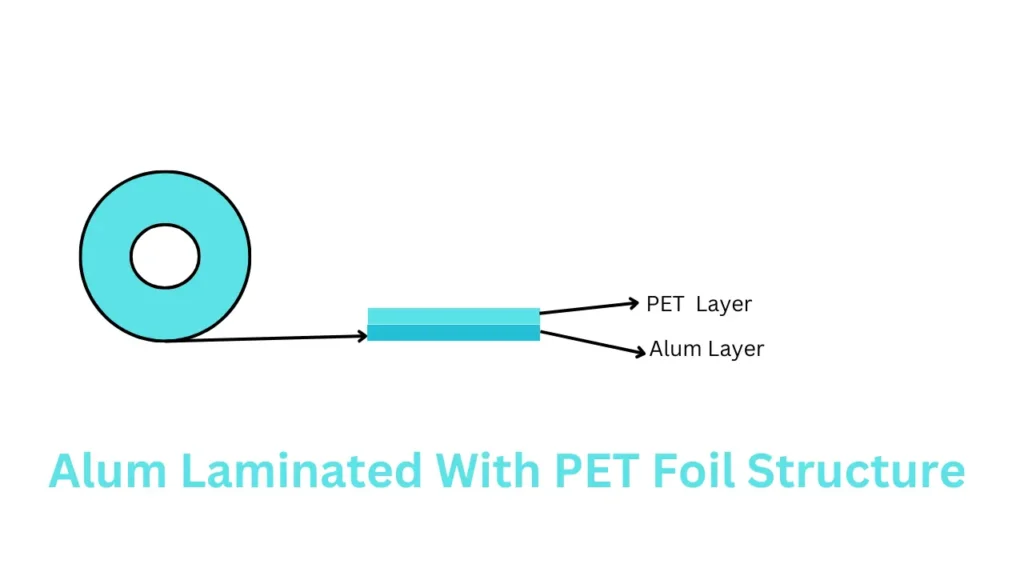

Alum laminated PET Foil is made from a thin aluminium foil coated with PET (polyethylene terephthalate). Laminating aluminum with PET foil involves bonding these two materials together. The PET layer is typically bonded to the aluminum sheet using adhesives or heat. This process enhances the durability, flexibility, and protective qualities of the aluminum while retaining its barrier properties.

The alum laminated PET foil is used in pharmaceutical finished product packaging in the form of blister packaging, the finished products are tablets and capsules.

- Description

The aluminum layer is laminated with a PET (Polyethylene terephthalate) layer. One side is plain and the other side is printed or unprinted.

2. Text Matter

If the foil is printed, match the sample with a shade card, or artwork.

3. Color

The Alum laminated with pet foil is printed with text matter color to match the shade card or Pantone card.

4. Width

The selected foil measured the width with the help of a measuring scale.

5. Inner core diameter

This test measures the inner core and the diameter of the roll. The foil roll was measured with the help of a measuring scale

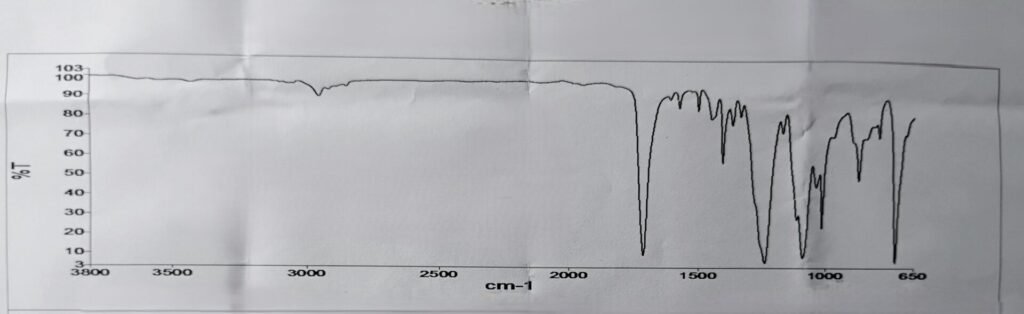

6. Identification by FTIR

The identification of the alum laminated with pet foil testing is the PET layer. Take sufficient samples of PET Layers. For the Comparison sample with the PET reference standard, first scan the reference standard then after the PET layer sample,

Then, the spectrum obtained from the specimen exhibits major absorption bands only at the same wavelengths as the spectrum of PET (polyethylene terephthalate) RS.

7. Grammage:

- Total Grammage:

the total grammage of alum laminated with pet foil, Take the sample Alum laminated with pet foil cut the sample 10 x 10 cm or 5 x 5 cm with the help of a GSM plate, take the weight at analytical balance then calculate by the given formula,

Total Grammage= weight in gram x 100 or 400 (if the sample cut 10 x 10 or 5 x 5 cm)

- For pet layer

Take the sample of the total Grammage completely and dip the sample in a glass beaker containing 10 % sodium hydroxide solution for 30 min the aluminium layer dissolves. The remaining sample is the PET layer. Dry the sample in a hot air oven for 2 min at 700c. After drying the layer cool then take the weight, after calculation by the given formula,

Grammage of PET layer = weight in grams x 100 or 400 (if the sample cut 10 x 10 or 5 x 5 cm)

- For Alum Layer:

Grammage of alum layer= total Grammage- Grammage of pet layer

8. Identification of aluminium

The identification of aluminium , Weigh the sample aluminium layer of 15 mg sample and put it in a beaker mixing 30ml 1NHCL then heat the beaker aluminium foil to dissolve, in solution add about 1 ml HCL and 1 ml of thioacetamide regents, no precipitate is formed, add dropwise NaoH solution, a gelatinous white precipitate is formed which dissolve on further addition of 1NaoH Solution after gradually addition ammonium hydroxide solution .gelatinous white precipitate is re-formed.

9. Thickness:

- Total thickness:

The selected sample of Alum Laminated with PET foil measure with the help of measuring digital micrometer. Take the reading and record the reading.

- For PET Layer:

The sample of Grammage testing of the PET Layer is taken to measure the sample with the help of a digital micrometer. Take the reading and record the reading.

10. Pinhole:

Take the sample of Alum Laminated with PET Foil test performed by Illuminated magnifier tester instrument. Its instruments are in the background white light. Put the sample on the front of the bench. We neck eye verify the sample. Ensure the sample has no pine holes. It is easily identify the foil is no pinhole.

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] The Alum/PET foil is made of the aluminium layer laminated with a PET (Polyethylene terephthalate) layer. It is two types of foil printed and unprinted. The foil is printed on the aluminium layer side. The PET side layer is in contact with the drugs. Foil is used in the packaging of pharmaceutical finished products such as tablets, capsules, and bulk products. Its foil is used to secure the moisture, air, heat, and other environmental conditions. Its foil is better for sensitive product packaging. […]

[…] PET/Alum/PA/LDPE Foil is made of an Aluminium layer laminated with a PET (polyethylene terephthalate) Layer on one side and the other side Aluminium layer laminated with PA […]

[…] made from cardboard, aluminium foil, adhesive, and sealing film like LDPE. Tagger seal has a wide range of uses it can be used to seal […]

[…] three-layered structure made of polyester laminated with aluminium foil which in turn is laminated low-density polyethylene […]

[…] test is performed by FTIR instrument, Pp-coated aluminium foil is in contact with the drug so the contact layer is polypropylene then we identification test […]