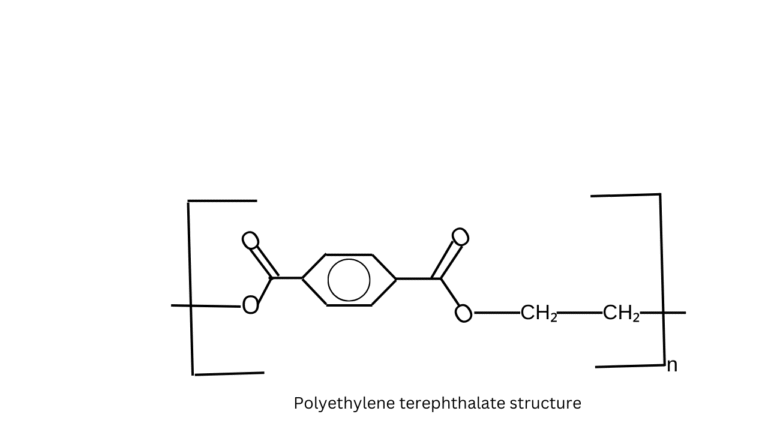

What is PET

PET (polyethylene terephthalate) is the polyester family of polymers. that has general-purpose linear semi-crystalline thermoplastic polymer. It is made from an esterification reaction between terephthalic acid and ethylene glycol. PET consists of repeating (C10H8O4) units. PET is commonly recycled, and has the digit 1 as resin identification Number Code.

It is used in the textile industry as a polyester fiber. Polyester fibers are used in fashion apparel often blended with cotton. It is used in pharmaceutical liquid finished product packaging in PET rigid bottles and containers. Many different colors and packing styles. It is transparent and natural color making the product branding.

It uses pharmaceutical finish product tablets, capsules, and sachet packing. It is laminated form with aluminum foil and PVC. Its laminated forms are PVC/Aluminum/PET, which is a cold-form foil packaging.

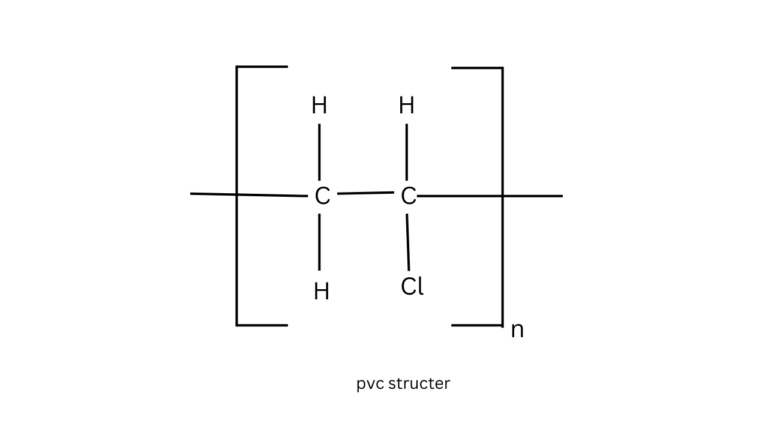

What is PVC

PVC (polyvinyl chloride) is a thermoplastic polymer made from chloromethane monomer. This polymer may be a quite common polymer material alongside polyethylene and polypropylene. PVC consists of repeating (CH2-CHCl) units.

PVC is used in pharmaceutical packaging in finished products of tablets, and capsules, in the form of rigid packaging, cold form packaging, alu-alu packaging, and other forms of packaging. PVC laminated with PVDC, ALUMINIUM, PAPER, PET, and Heat Seal Lacquered form,

Differences Between PVC and PET

- Chemically Composition

- PET (Polyethylene terephthalate): PET is a polymer made from ethylene glycol and terephthalic acid.

- PVC (Polyvinyl chloride): PVC is made from the polymerization of vinyl chloride monomers.

2. Properties

A) Transparency:

- PET: it is highly transparent and is often used in packaging where clarity is important.

- PVC: it can be transparent but is generally more opaque than PET

B) Strength

- PET: It has good tensile strength and is relatively lightweight.

- PVC: it is known for its durability and resistance to abrasion. It can be made flexible or rigid.

C) Recyclability:

- PET: It is widely recycled, especially in the form of pharmaceutical Bottle and container

- PVC: it is commonly recycled compared to PET and releases harmful chemicals if disposed of improperly.

3) uses

- PET: it is used in food and beverage packaging such as bottles, containers of pharmaceutical finish tablets, powder, and capsule packaging. Used in polyester fiber in pharmaceutical packaging in container packaging

- PVC: construction (pipe, window frame, flooring). Employed in medical devices (tubing, IV bags). Pharmaceutical finished product packaging laminated form PVC/PVDC, PVC/PE/PVDC, PVC/Alum/PET, in from strip packaging, Sachet,

4) Environmental Impact

- PET: generally considered more environmentally friendly due to its higher recyclability, however, the production of PET involves the use of non-renewable resources.

- PVC: it has a greater environmental impact due to the release of hazardous chemicals during production and disposal. It is also less recyclable than PET

5) Cost

- PET: generally more expensive than PVC due to the cost of raw material and processing

- PVC: its trend to be cheaper, especially in applications requiring large quantities such as pharmaceutical finish product packaging

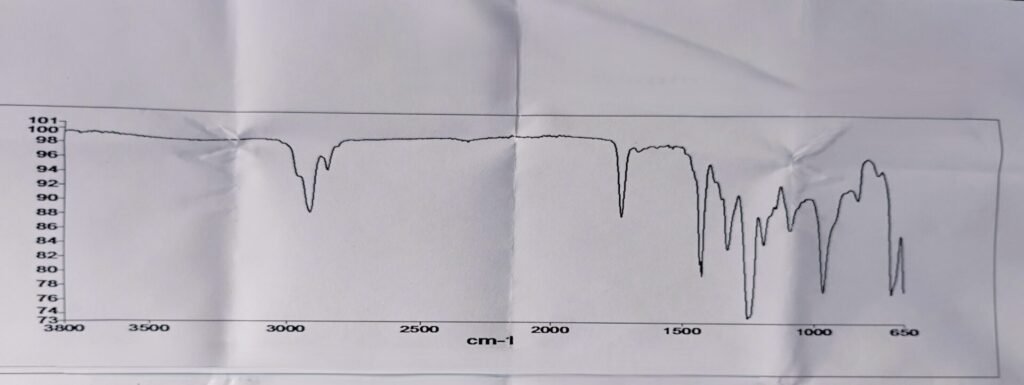

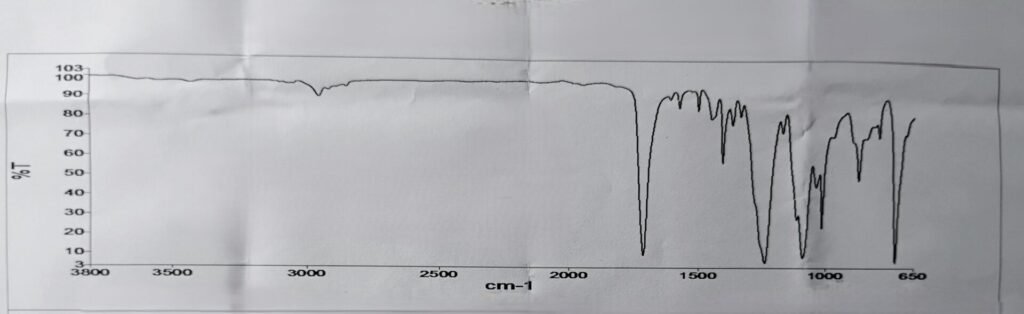

6) Identification test for FTIR

PVC FTIR Graph

PET FTIR Graph

Why Use PET Plastic in Pharmaceutical Packaging

The pharmaceutical industry uses packaging of tablets, capsules, liquid, and bulk finish products, the benefit of using PET (Polyethylene terephthalate) plastic.

- Product protection: PET Bottles have the most barrier properties to protect from light, air, moisture, and other environmental conditions and foreign particles. The safe grading of the product its quality its potency and the stability of the product in all climate zones.

- Transparency and visibility: When the pet is in the form of a pet bottle. Its properties are the transparency of the pet plastic the pharmaceutical products are easy inspection of the product. It helps the condition of pharmaceutical products inside and outside of the PET bottle. The physical condition appears the presence time of the tablets, capsules, and liquid finish pharmaceutical products. Then it helps the branding of the products.

- Versatility: The PET Bottle is allowed to easily mold in different sizes and designs. The different pharmaceutical products are liquid, powder, and solid doses. It allows different styles of packaging to customize the finished product packaging. It helps improve the packaging style. Easy to package. Branding and looking at the different innovations in the packaging material

- Chemical resistance: It’s made from chemically inert polymers hence they do not react to substances. The pharmaceutical products’ liquid, powder, and solid doses are safe without any loose physical, or chemical properties. It stores the inert reaction and other contamination chemically and biologically in all climate zones hence the improvement of the stability of the pharmaceutical products. It increases the shelf life of the products.

- Cost-effectiveness: Pet plastic or pet laminated foil is relatively inexpensive to produce. The pharmaceutical packaging of the finished product packing it is cost-effective. It has some properties compared to other plastic like glass.

- Lightweight and durability: Pet plastic makes the bottles. The pharmaceutical products packaging tablets, liquids, and capsules, powder are lightweight then easily used, and easy to carry the patience of medicinal products, its durability and the uses time missed the hand does not easily break the pet bottle. Then the results are a good feeling for customers and patients. It’s made a win-win situation for the customer and manufacturer.

- Eco-friendly with environment: Pet plastic is easier to produce than glass and other plastic. It is easily recycled then less carbon is used in production. It is lighter than transpiration the vehicle has less carbon emission and less energy required for transportation and its maintenance cost is reduced. Over its plastic is eco-friendly than comparison other plastic and glass

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] Grammage– Take the sample of a combination layer of paper/ Polyethylene terephthalate (PET)/Aluminium/Heat seal lacquer. Cut the sample of 10 x 10 cm with the help of a GSM plate. Take […]

[…] layer foil made from the structure is, the aluminum thin layer is a combination of one side of PET (Polyethylene Terephthalate) and the other side is Low-density polyethylene. The aluminium is sandwiched. The drug contact layer […]

[…] PET (Polyethylene terephthalate) layer is combined with LDPE (Low-density polyethylene). The combination of PET and coated LDPE results in a multi-structure that leverages the benefits of both materials, […]

[…] terephthalate). Laminating aluminum with PET foil involves bonding these two materials together. The PET layer is typically bonded to the aluminum sheet using adhesives or heat. This process enhances the […]

[…] a sample of PET Layer Grammage sample measuring the sample with the help of a digital micrometer, take a reading, and note […]

[…] It is multi-structure foil. It foil is the inner side of the LDPE Layer, and the outer side is the PET layer. This foil is used in the packaging of pharmaceutical finished product tablets, capsules, and bulk […]

[…] sample of PVC/Aclar/Alum foil structure is made of aclar and is laminated with the PVC and another side is […]

[…] It is two types of foil printed and unprinted. The foil is printed on the aluminium layer side. The PET side layer is in contact with the drugs. Foil is used in the packaging of pharmaceutical finished products […]

[…] foil is a primary packaging material. Its foil combines aluminum foil between nylon (OPA) OR Polyester (PET), PVC, or PVC/PVDC layers. Its foil is also called cold-formed blister foil. the lidding foil use, and […]