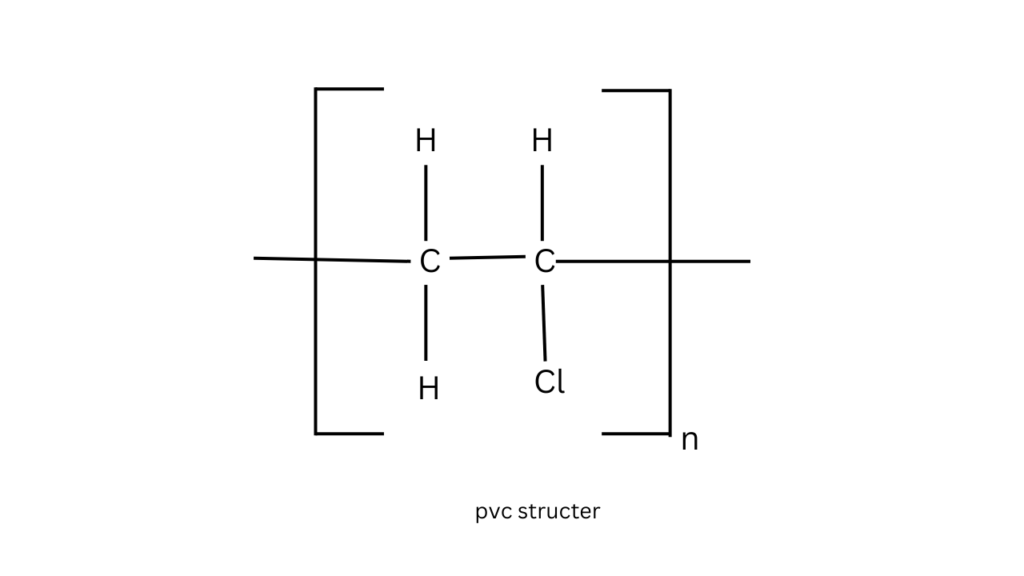

PVC Foil

The PVC is full-name polyvinyl chloride.it is a thermoplastic polymer made from chloroethane monomer. This material may be a quite common polymer material alongside polyethylene and polypropylene. the PVC used in pharmaceutical industries is 0.2mm to 0.8mm. The higher the thickness greatly influences the light barrier property, because the higher the thickness, the lower the percentage of light that passes through the material.

It has a transmittance of up to 80% between 300 and 400nm, differing from that which is currently required in pharmacopeia a transmittance of at most 25 % and 20 % respectively, within a wavelength range between 290 and 450 nm.

Its properties are low permeability height safety, excellent thermoform ability compatibility with other materials, cost-effectiveness, and recyclability.

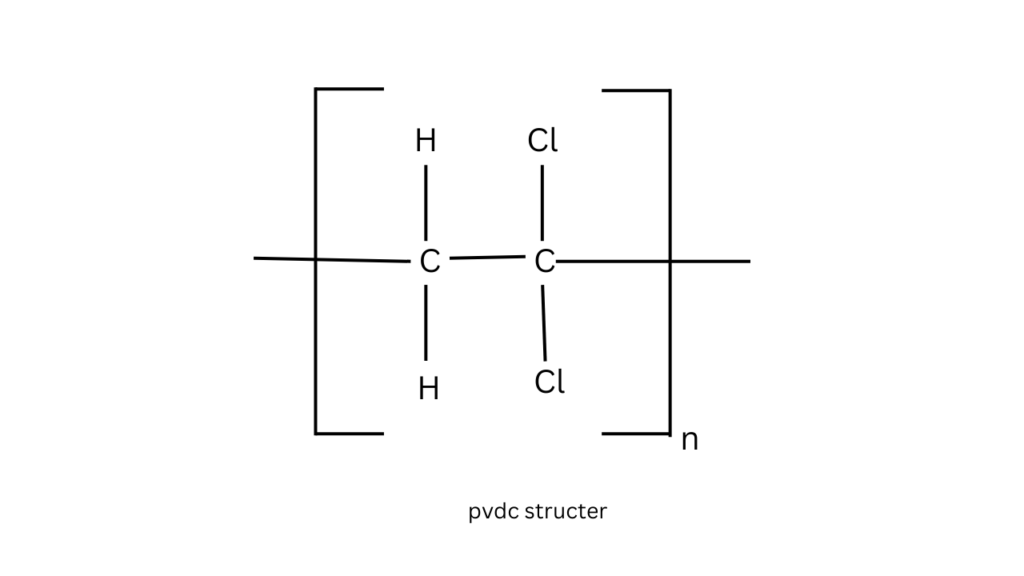

PVDC stands for polyvinylidene chloride, a homopolymer of vinylidene chloride (VDC). This is material uses a barrier of water, oxygen, and aromas. PVDC plays a critical role in blister packaging as lamination or coating on PVC. PVDC can reduce the gas and moisture permeability of PVC blister packages by a factor of 5-10.

PVDC Foil

the PVDC is full-name polyvinylidene chloride. it stands for polyvinylidene chloride, a homopolymer of vinylidene chloride (VDC). This material uses a barrier of water, oxygen, and aromas. PVDC plays a critical role in blister packaging, such as lamination or coating on PVC. PVDC can reduce the gas and moisture permeability of PVC blister packages by 5-10. It is a combination in product packaging of layers of PVC/PVDC, PVC/PE/PVDC,

Monomer

- PVC- Vinyl chloride (CH2=CHCl)

- PVDC- Vinylidene chloride (CH2=CCl2)

Rigidity

- PVC- Generally rigid and strong, especially in its pure form

- PVDC-more flexible and softer than PVC due to its less crystalline structure

Tg (glass transition temperature)

- PVC- Relatively High Contributing To Its Rigidity

- PVDC-lower than PVC, Which makes PVDC more flexible at room temperate

Thermal stability

- PVC- it is less stable at higher temperatures, and additives are often required to enhance its heat resistance

- PVDC- it has good stability but can degrade at high temp. releasing hydrochloric acid

Application

- PVC-it is used in construction material, electronic insulation, packaging, medical device

- PVDC- it is used in packaging food preservation, specialized film

Cost

- PVC- generally lower cost, widely available, and used in a broad range of applications

- PVDC- more expensive than PVC due its specialized properties and lower production volume

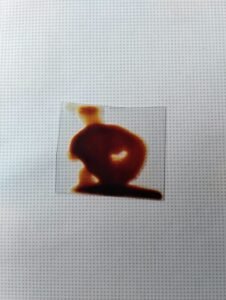

Morpholine test for PVDC and PVC

PVC layer not reaction with morpholine regent

PVDC layer reaction with morphiline Regent results made yellowish color produced

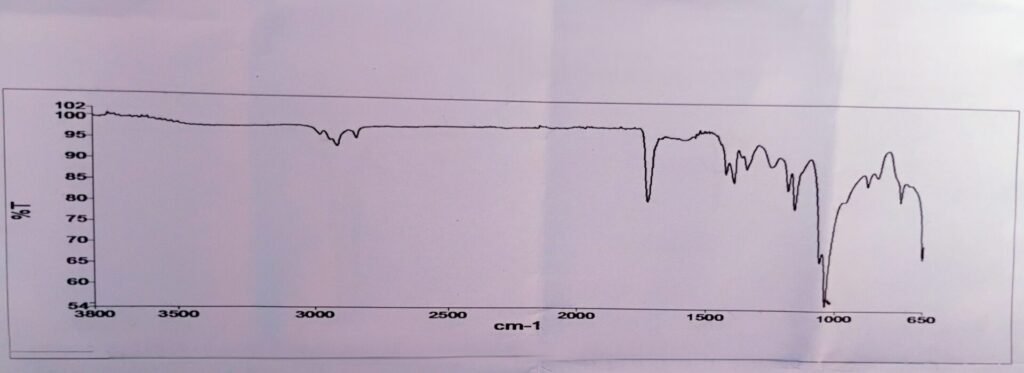

Identification test by FTIR of PVC And PVDC

FTIR test of PVC layer

FTIR test of PDVC layer

Molecular Structure diagram of PVC and PVDC

Why the PVC rigid than PVDC

PVC Layer

PVC is rigid because of the strong intermolecular forces between the polymer chains, especially due to the presence of the polar chlorine atoms. These chlorine atoms increase the attraction between the chains making the material more crystalline and less flexible additionally PVC has a higher glass transition temperature (Tg), meaning it remains in a rigid state a room temperature,

PVDC Layer

PVDC is softer than PVC primarily because the additional chlorine atom in each monomer unit creates a bulkier structure. This bulkiness hinders the close packaging of the polymer chain, reducing the strength of intermolecular forces and resulting in a less crystalline, more amorphous structure, the reduced crystallinity and lower (Tg) make PVDC more flexible and softer compared to PVDC

I am Maneesh Maurya a professional pharmaceutical blogger from India having rich experience in the pharmaceutical Quality control field.

[…] The identification of sample PVC/PVDC/Alum foil is testing of the layer PVC Layer side. The identification testing of PVC Layer with the help of FTIR instrument. The PVC layer matches with the PVC reference standard. The first scan is the reference standard of the PVC layer, then after scanning the graph PVC layer sample, the sample of PVC Layer, and reference standard PVC sample are graph plotted between 3800-650 cm-1 wavelength. […]

[…] clear transparent PVC film made of thermoplastic. Color and transparent. Both side surfaces are smooth. Verify the dust […]

[…] sample of Alum/PVDC foil total Grammage testing cut the 10 x 10 cm2 or 5 x 5 cm2 (as applicable) with the help of GSM Plate. […]